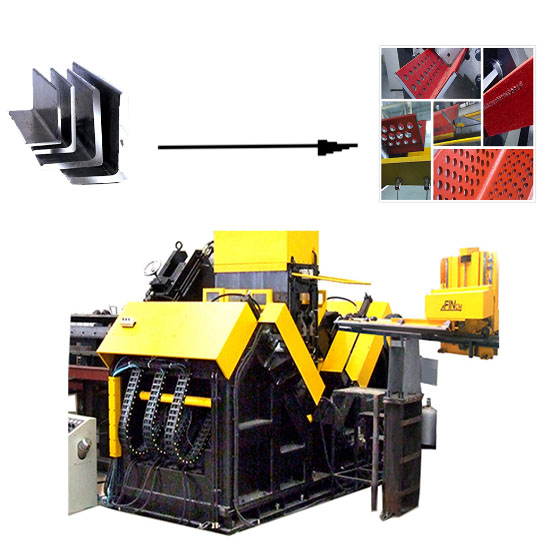

Mashiinka Xidhitaanka iyo Calaamadaynta Qodista CNC ee Xaglaha Birta

| MAYA. | Shay | Halbeegga | |||

| ADM3635 | BL3536 | ADM2532 | BL2532 | ||

| Cabbirka xagasha | 140 *140 *10 mm- 360 *360 *35 mm | 140 *140 *10 mm- 250 *250 *32mm/ | |||

| Kala duwanaanshaha garoomada ciyaaraha | 50mm-330mm (aan tallaabo lahayn)) | 50mm-220mm (aan tallaabo lahayn)) | |||

| Tirada lo'da qodaysa dhinac kasta | Arbitrariness | ||||

| Tirada dunmiiqa qodista dhinac kasta | 3 | ||||

| Kala duwan ee dhexroorka qodista (birta adag) | φ17.5mm~ φ40mm | φ17.5 mm ~ φ26mm | |||

| Tirada dhidibka CNC | 9 | 3 | 9 | 3 | |

| Dhererka ugu badanxagal | 12 mitir | ||||

| Xawaaraha quudinta xagasha | 40 m/daqiiqo | ||||

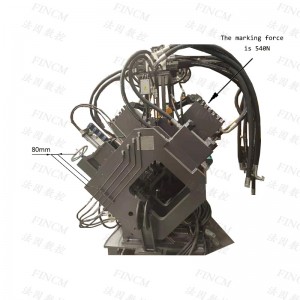

| Xoogga Calaamadaynta | 1030KN | ||||

1. Heer sare oo otomaatig ah. Khadka wax soo saarka waxa uu ku qalabaysan yahay qalab quudin otomaatig ah iyo gudbiye quudin oo isdhaafsan.

2. Dhammaan godadka iyo lambarrada/xarafyada calaamadaynta ee ku yaal agabka xagasha waxaa si toos ah u farsamayn kara khadka wax soo saarka hal mar.

3. Saxnaanta booska ee sameynta godadka waa mid aad u sareysa.

4. Hufnaanta qodista iyo tayada qodista ayaa sarreeya. Qaybta qodista waxaa ku qalabaysan lix kooxood oo awood qodis CNC ah.

5. Waxaa jira saddex kooxood oo qodis ah dhinac kasta oo ka mid ah walxaha xagasha.

6. Qalabka qodista waxaa ku qalabaysan farsamo otomaatig ah oo loogu talagalay in lagu xidho diskka.

7. Gacantu aad bay ugu habboon tahay.

8. Nidaamka qaboojinta MQL (tirada ugu yar ee saliidda) waa nidaamka qaboojinta ugu horumarsan adduunka.

| Maya. | Magaca | Summada | Waddan |

| 1 | Matoorka Adeegga AC | Panasonic/Siemens | Jabaan/Jarmalka |

| 2 | Tilmaamaha Toosan | Hiwin/CSK | Taiwan Shiinaha |

| 3 | Xidhmo dabacsan | KTR | Jarmalka |

| 4 | Kala-goyska Rotary | Dublin | Mareykanka |

| 5 | Waalka Haydarooliga | ATOS/Yuken | Talyaaniga/Japan |

| 6 | Cutubka isku dhafan ee pneumatic | SMC/HawadaTAC | Jabaan/Taiwan Shiinaha |

| 7 | Waalka hawada | AirTAC | Taiwan Shiinaha |

| 8 | Silsilad | AirTAC | Taiwan Shiinaha |

| 9 | CPU | Mitsubishi | Jabaan |

| 10 | Qaybta meelaynta | Mitsubishi | Jabaan |

| 11 | Bamka laba-geesoodka ah | Albert | Mareykanka |

| Qaybta Jihaynta | Yokogawa | Jabaan | |

| 12 | Xakameeyaha barnaamijka | Yokogawa | Jabaan |

| 13 | Beddelka u dhowaanshaha | AUTONICS | Kuuriya |

| 14 | waalka elektromagnetic-ka | ATOS/Yuken | Talyaaniga |

| 15 | Rwaalka badbaadada | ATOS/Yuken | Talyaaniga |

| 16 | Waalka yaraynta cadaadiska | ATOS/Yuken | Talyaaniga |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda

Macluumaadka Warshadda

Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Ganacsiga