Mashiinka Qodista Godka Qotoda Dheer ee CNC ee Jiifka ah ee Dual-spindle

| Shay | Magaca | Qiimaha halbeegga | |||||

| DD25N-2 | DD40E-2 | DD40N-2 | DD50N-2 | ||||

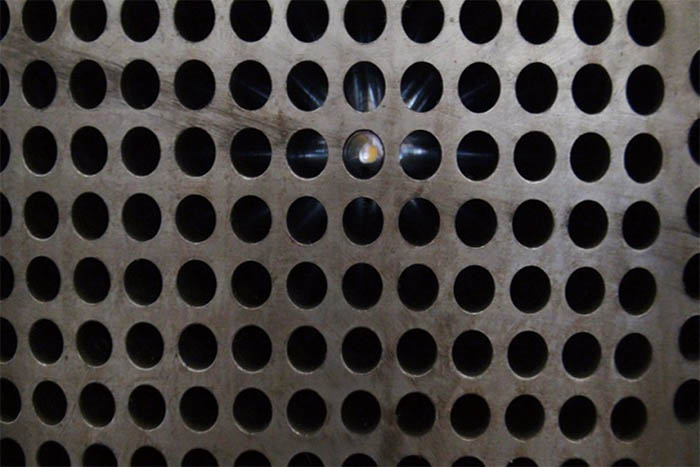

| Cabbirka saxanka tuubada | Ugu badnaanqodisdhexroor | φ2500mm | Φ4000mm | φ5000mm | |||

| Dhexroorka godka ceelka | Birta BTA | φ16~φ32mm | φ16~φ40mm | ||||

| Qoto dheer ee ugu badan ee qodista | 750mm | 800mm | 750mm | ||||

| QodistaSpindle | Tirada | 2 | |||||

| Masaafada dhexe ee isbuunyada (la hagaajin karo) | 170-220mm | ||||||

| Spindledhexroorka dhalista hore | φ65mm | ||||||

| Xawaaraha dunmiiqa | 200~2500r/daqiiqo | ||||||

| Awoodda matoorka soo noqnoqoshada isbeddelka leh ee isbedbeddela ee isbedbeddelka ah ... | 2 × 15kW | 2 × 15Kw/20.5KW | 2 × 15kW | ||||

| Dhaqdhaqaaqa sibidhka dheer (X-dhidibka) | Stroke | 3000mm | 4000mm | 5000mm | |||

| Xawaaraha ugu badan ee dhaqdhaqaaqa | 4m/daqiiqo | ||||||

| Awoodda matoorka adeegga | 4.5kW | 4.4KW | 4.5kW | ||||

| Dhaqdhaqaaqa sibidhka toosan ee tiirka (Dhidibka Y) | Stroke | 2500mm | 2000mm | 2500mm | |||

| Xawaaraha ugu badan ee dhaqdhaqaaqa | 4m/daqiiqo | ||||||

| Awoodda matoorka adeegga | 4.5KW | 7.7KW | 4.5KW | ||||

| Dhaqdhaqaaqa labanlaabka ah slide quudinta dunmiiqa (dhidibka Z) | Stroke | 2500mm | 2000mm | 900mm | |||

| Heerka quudinta | 0~4m/daqiiqo | ||||||

| Awoodda matoorka adeegga | 2KW | 2.6KW | 2.0KW | ||||

| Nidaamka Haydarooliga | Cadaadiska / socodka bamka haydarooliga | 2.5~5MPa,25L/daqiiqad | |||||

| Awoodda mootada ee bamka haydarooliga | 3kW | ||||||

| Nidaamka qaboojinta | Awoodda taangiga qaboojinta | 3000L | |||||

| Awoodda qaboojiyaha warshadaha | 28.7kW | 2 * 22KW | 2 * 22KW | 2 * 14KW | |||

| Enidaamka korontada | CNCnidaamka | FAGOR8055 | Siemens828D | FAGOR8055 | FAGOR8055 | ||

| TiradaCFaasas NC ah | 5 | 3 | 5 | ||||

| Awoodda guud ee matoorka | Ku dhawaad 112KW | Ku saabsan125KW | Ku dhawaad 112KW | ||||

| Cabbirrada mashiinka | Dhererka × ballaca × dhererka | Qiyaastii 13×8.2×6.2m | 13*8.2*6.2 | 14 * 7 * 6m | 15 * 8.2 * 6.2m | ||

| Miisaanka mashiinka | Qiyaastii 75tkuwa | Ku saabsan70tons | Qiyaastii 75tkuwa | Qiyaastii 75tkuwa | |||

| Saxnaanta | Saxnaanta booska dhidibka X | 0.04mm/ dhererka guud | 0.06mm/ dhererka guud | 0.10mm/ dhererka guud | |||

| Saxnaanta booska ku celcelinta dhidibka X | 0.02mm | 0.03mm | 0.05mm | ||||

| Saxnaanta booska eeY-dhidibka | 0.03mm/ dhererka guud | 0.06mm/dhererka guud | 0.08mm/dhererka guud | ||||

| Saxnaanta booska ku celcelinta dhidibka Y | 0.02mm | 0.03mm | 0.04mm | ||||

| Dulqaadka godkaskala fogaanshaha | At QodistaAlbaabka Qalabka Face | ±0.06mm | ±0.10mm | ±0.10mm | |||

| At DhooliQalabka Dhoofinta Wajiga | ±0.5mm/750mm | ±0.3-0.8mm/800mm | ±0.3-0.8mm/800mm | ±0.4nn750mm | |||

| Wareegga godka | 0.02mm | ||||||

| Cabbirka godkasaxnaanta | IT9~IT10 | ||||||

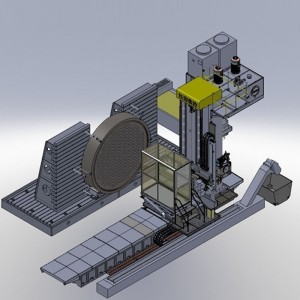

1. Mashiinkan waxaa iska leh mashiinka qodista godka qoto dheer ee toosan. Saxnaanta sariirta shubka waa mid deggan, kaas oo ay ku taal miis simbiriirixan oo dhererkiisu dheer yahay, kaas oo u shaqeeya inuu qaado tiirka dhaqdhaqaaqa dhererka (jihada X); tiirka waxaa ku qalabaysan miis simbiriirixan oo toosan, kaas oo qaada miiska simbiriirixan ee quudinta simbiriirixan ee dhaqdhaqaaqa toosan (jihada Y); miiska simbiriirixan ee quudinta simbiriirixan ayaa dhaqaajinaya ismbiriirixanka dhaqdhaqaaqa quudinta (jihada Z).

2. Dhidibka X, Y iyo Z ee mashiinka waxaa dhammaantood hagaya lammaane hagayaal toosan oo duuban, kuwaas oo leh awood qaadis aad u sarreysa iyo waxqabad jawaab celin firfircoon oo heer sare ah, aan lahayn farqi iyo saxnaan dhaqdhaqaaq oo sare.

3. Miiska shaqada ee mashiinka ayaa laga soocay sariirta, si walxaha la xirxiray aysan u saameyn gariirka sariirta. Miiska shaqada waxaa laga sameeyay bir la shubay oo leh saxnaan deggan.

4. Mashiinku wuxuu leeyahay laba wareeg, kuwaas oo isku mar shaqayn kara. Hufnaanta mashiinku waxay ku dhowdahay labanlaab ka badan mashiinada hal wareeg.

5. Mashiinku wuxuu ku qalabaysan yahay qalab silig fidsan oo otomaatig ah oo ka saaraya jajabka. Jajabyada birta ah ee uu soo saaro qalabka qodista waxaa loo diraa qalabka ka saarista jajabka nooca silsiladda iyada oo loo marayo qalabka ka saarista jajabka, ka saarista jajabkuna si toos ah ayay u shaqaysaa.

6. Mashiinku wuxuu ku qalabaysan yahay nidaam saliidayn otomaatig ah, kaas oo si joogto ah u saliidayn kara qaybaha la saliidaynayo sida tareenka hagaha iyo boolal, si wax ku ool ah u hubinaya hawlgalka xasilloon ee mashiinka iyo hagaajinta cimriga adeegga qayb kasta.

7. Nidaamka xakamaynta tirooyinka Simens828D/ FAGOR8055 waxaa lagu qaataa nidaamka xakamaynta tirooyinka mashiinka, kaas oo ku qalabaysan giraangiraha gacanta ee elektaroonigga ah, sidaa darteed waa ku habboon tahay hawlgalka iyo dayactirka.

| NO | Magaca | Summada | Waddan |

| 1 | Ltareenka hagaha ee inear | HIWIN/PMI | Taiwan (Shiinaha) |

| 2 | CNCnidaamka | SIEMENS | Jarmalka |

| 3 | Qalabka yareeya qalabka meeraha | APEX | Taiwan (Shiinaha) |

| 4 | Kala-goyska qaboojinta gudaha | DEUBLIN | Mareykanka |

| 5 | Bamka saliidda | JUSTMARK | Taiwan (Shiinaha) |

| 6 | Waalka Haydarooliga | ATOS | Talyaaniga |

| 7 | Mashiinka adeegga quudinta | Panasonic | Jabaan |

| 8 | Beddel, badhan, iyo iftiinka tilmaame | Schneider/ABB | Faransiiska / Jarmalka |

| 9 | Nidaamka saliidaynta otomaatiga ah | BIJUR/HERG | Mareykanka / Jabaan |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga