Mashiinka Qodista Saxanka CNC ee Miiska Labaad ee PD16C

| Shay | Magaca halbeegga | Qiimaha halbeegga |

| Saxancabbirka | Saxandhumucda isku dhafan | Ugu badnaan.80mm |

| Ballaca*dhererka | 1000mm × 1650mm 1 xabbo | |

| 825mm × 1000mm 2 xabbo | ||

| 500mm × 825mm 3 xabbo | ||

| Dhexroorka qodista | Φ12mm-Φ50mm | |

| Habka xawaaraha isbeddela | Isbeddelka xawaaraha aan tallaabada lahayn ee Inverter | |

| Xawaaraha wareega(RPM) | 120-560r/daqiiqo | |

| Cunnada habaynta | Xeerarka xawaaraha aan lahayn tallaabada Haydarooliga | |

| Saxanqabsashada | Dhumucda xajinta | 15-80mm |

| Tirada dhululubada isku xidha | 12个 | |

| Xoogga qabsashada | 7.5KN | |

| Matoorka | Matoorka dunmiiqa | 5.5KW |

| Matoorka bamka Haydarooliga | 2.2KW | |

| Matoorka gudbiyaha jajabka | 0.4KW | |

| Matoorka bamka qaboojinta | 0.25KW | |

| Matoorka servo-ga X axis | 1.5KW | |

| Matoorka adeegga Y ee dhidibka | 1.0KW | |

| Cabbirka mashiinka | Dhererka*ballaca*dherert | qiyaastii3160*3900*2780mm |

| Wight | Mashiin | qiyaastii 4000kg |

| Nidaamka ka saarista jajabka | qiyaastii 400kg | |

| Stroke | Dhidibka X | 1650mm |

| Dhidibka Y | 1000mm |

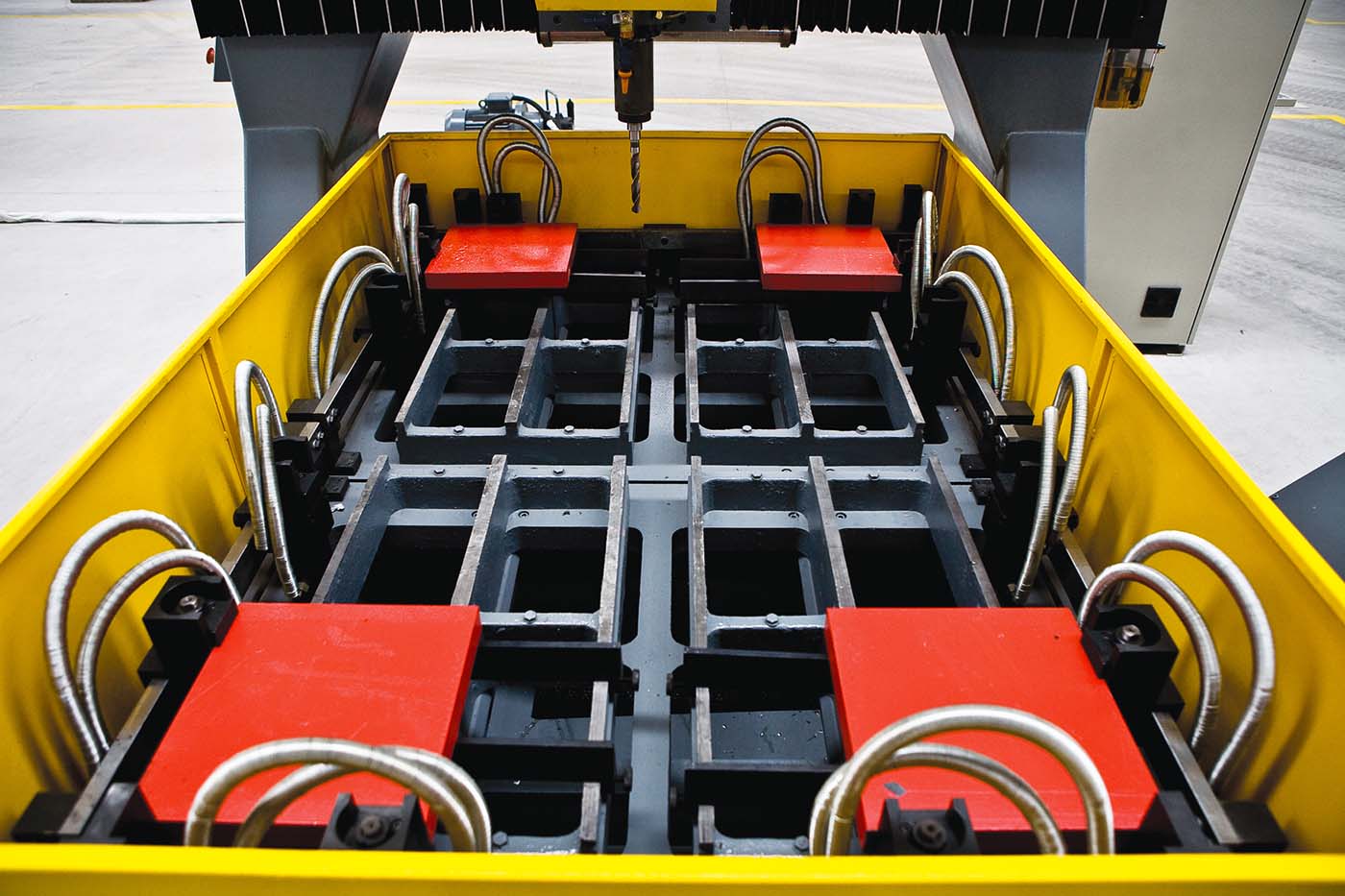

1. Mashiinkani wuxuu inta badan ka kooban yahay sariir, gantry, miiska wareejinta (miis labanlaab ah), madaxa korontada qodista, nidaamka haydarooliga, nidaamka xakamaynta, nidaamka saliidaynta dhexe, nidaamka ka saarista jajabka, nidaamka qaboojinta, qalabka isbeddelka degdega ah, iwm.

2. Mashiinkani wuxuu qaataa qaabka sariirta go'an iyo gaantry-ga dhaqaaqa. Gaantry-ga, sariirta iyo miiska shaqada dhammaantood waa qaab-dhismeedyo alxan leh, ka dib marka la daweeyo gabowga, saxnaantu waa mid deggan. Saxanka waxaa ku dhejiya qabsatooyin haydarooli ah, hawl-wadeenkana waxaa xakameeya badhanka cagta, kaas oo ku habboon oo badbaadin kara shaqada;

3. Mashiinkani wuxuu leeyahay 2 faas oo CNC ah: dhaqdhaqaaqa gantry (dhidibka x); dhaqdhaqaaqa madaxa korontada qodista ee ku yaal laambadda gantry (dhidibka y). Dhidib kasta oo CNC ah waxaa hagaya hage toosan oo toosan oo sax ah, kaas oo si toos ah u wada matoorka AC servo + boolal kubbadda ah. Dhaqdhaqaaq dabacsan iyo meelayn sax ah.

4. Madaxa korontada qodista ee kontoroolka otomaatiga ah ee haydarooliga waa tignoolajiyada shatiga leh ee shirkaddayada. Looma baahna in la dejiyo wax xuduudo ah ka hor inta aan la isticmaalin, beddelka u dhexeeya si dhakhso ah u socoshada, shaqada hore iyo dib u celinta degdegga ah si toos ah ayaa loo xaqiijiyaa iyada oo loo marayo ficilka isku dhafan ee korontada-haydarooliga.

5. Qalabkan mashiinka ah wuxuu qaataa nidaam saliidayn dhexe halkii uu ka ahaan lahaa hawlgal gacanta ah si loo hubiyo in qaybaha shaqeynaya si fiican loo saliideeyo, loo hagaajiyo waxqabadka qalabka mashiinka, loona dheereeyo cimrigiisa adeegga.

6. Barnaamijka xakamaynta wuxuu qaataa barnaamijka barnaamijyada kombiyuutarka ee sare kaas oo la jaanqaadaya kantaroolka barnaamijaysan ee si madax-bannaan u sameeyay shirkaddayadu.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga