Mashiinka qodista moobaylka ee PLM Taxanaha CNC Gantry

| Item | Name | xuduudaheedu | |||

| PLM3030-2 | PLM4040-2 | PLM5050A-2 | PLM6060-2 | ||

| Mashiinka ugu badanagabcabbirka | Dhererka x ballaca | 3000*3000 mm | 4000 ×4000 mm | 5000 ×5000 mm | 5000 ×5000 mm |

| Dhumucda saxanka ugu badan ee la warshadeeyay | 250 mm, La cabbiri karo ilaa 380mm | ||||

| Shaqadamiis | Cabbirka Miiska Shaqada | 3500 × 3000 mm | 4500 ×4000 mm | 5500 ×4000 mm | 5500 ×4000 mm |

| Ballaca godka T | 28 mm | ||||

| Lboolal qaada | 3tkuwa/㎡ | ||||

| QodistaSpindle | Ugu badnaanqodisdhexroorka godka | φ60 mm | |||

| Saamiga ugu badanDhererka Qalabka iyo Dhexroorka Godka | ≤10(Taajkacarbidedaloolin) | ||||

| SpindleRPM | 30-3000 r/daqiiqo | ||||

| Isgoyska | BT50 | ||||

| Awoodda matoorka dunmiiqa | 2 × 22kW | ||||

| Xuddunta ugu badan ee dunmiiqan≤750r/daqiiqo | 280Nm | ||||

| Masaafada u dhaxaysa wejiga hoose eedunmiiqamiiska shaqada | 280—780 mm (Hagaaji sida waafaqsanagabdhumucdiisuna waa) | ||||

| Dhaqdhaqaaqa dhererka ee la gashan karo (dhidibka x) | Istaroog ugu badan | 3000 mm | 4000 mm | 5000 mm | |

| Xawaaraha dhaqaaqa dhidibka X | 0—8m/daqiiqo | ||||

| Awoodda matoorka servo-ga ee X-dhidibka | 2 × 2.7kW | ||||

| Psaxnaanta isbeddelka | Dhidibka X、Dhidibka Y | 0.06mm/ oo dhanistaroog | 0.08mm/ oo dhanistaroog | 0.10mm/ oo dhanistaroog | |

| Saxnaanta booska ku celcelinta | Dhidibka X、Dhidibka Y | 0.035mm/ oo dhanistaroog | 0.04mm/ oo dhanistaroog | 0.05mm/ oo dhanistaroog | |

| Nidaamka Haydarooliga | Cadaadiska / socodka bamka haydarooliga | 15MPa / 25L/daqiiqo | |||

| Awoodda matoorka bamka Haydarooliga | 3.0 kW | ||||

| Nidaamka sambabbada | Cadaadiska sahayda hawada | 0.5 Mpa | |||

| Ka saarista iyo qaboojinta jajabka | Nooca gudbiyaha jajabka | Silsilad fidsan | |||

| Tirada qalabka gudbiya jajabka | 2 | ||||

| Xawaaraha ka saarista jajabka | 1m/daqiiqad | ||||

| Awoodda matoorka gudbiyaha jajabka | 2 × 0.75kW | ||||

| Habka qaboojinta | Qaboojinta gudaha + qaboojinta dibadda | ||||

| Cadaadiska ugu badan | 2MPa | ||||

| Socodka ugu badan | 2 × 50L/daqiiqo | ||||

| Nidaamka korontada | CNC | Siemens 828D | |||

| CNCdhidibkaLambar | 6 | ||||

| Wadarta awoodda matoorka | Qiyaastii75kW | ||||

| Cabbirrada guud ee qalabka mashiinka | Dhererka × Ballaca × Sare | Ku saabsan 8m × 8m × 3m | Ku saabsan9m×9m×3m | Ku saabsan10m×10m×3m | Ku saabsan10m×10m×3m |

| Miisaanka guud ee qalabka mashiinka | Qiyaastii 32t | Ku saabsan40t | Ku saabsan48t | ||

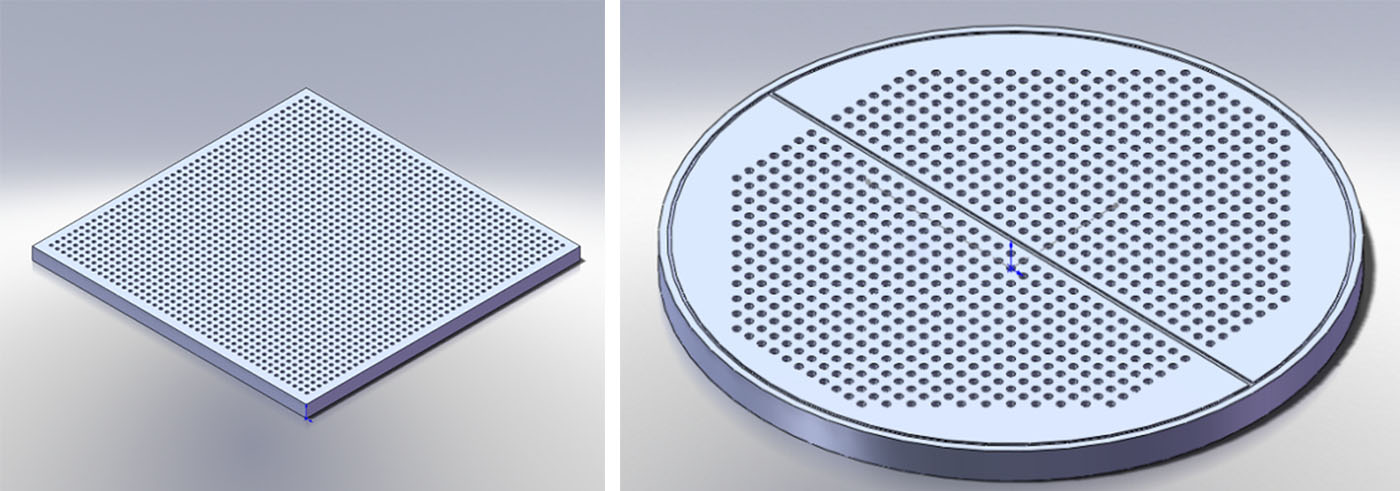

1. Mashiinkani wuxuu inta badan ka kooban yahay sariir iyo tiir, miis siman iyo miis simbiriirixan, sanduuqa korontada qodista nooca ram-ka toosan, miiska shaqada, qalabka gudbiyaha jajabka, nidaamka haydarooliga, nidaamka neef-mareenka, nidaamka qaboojinta, nidaamka saliidaynta dhexe, nidaamka korontada, iwm.

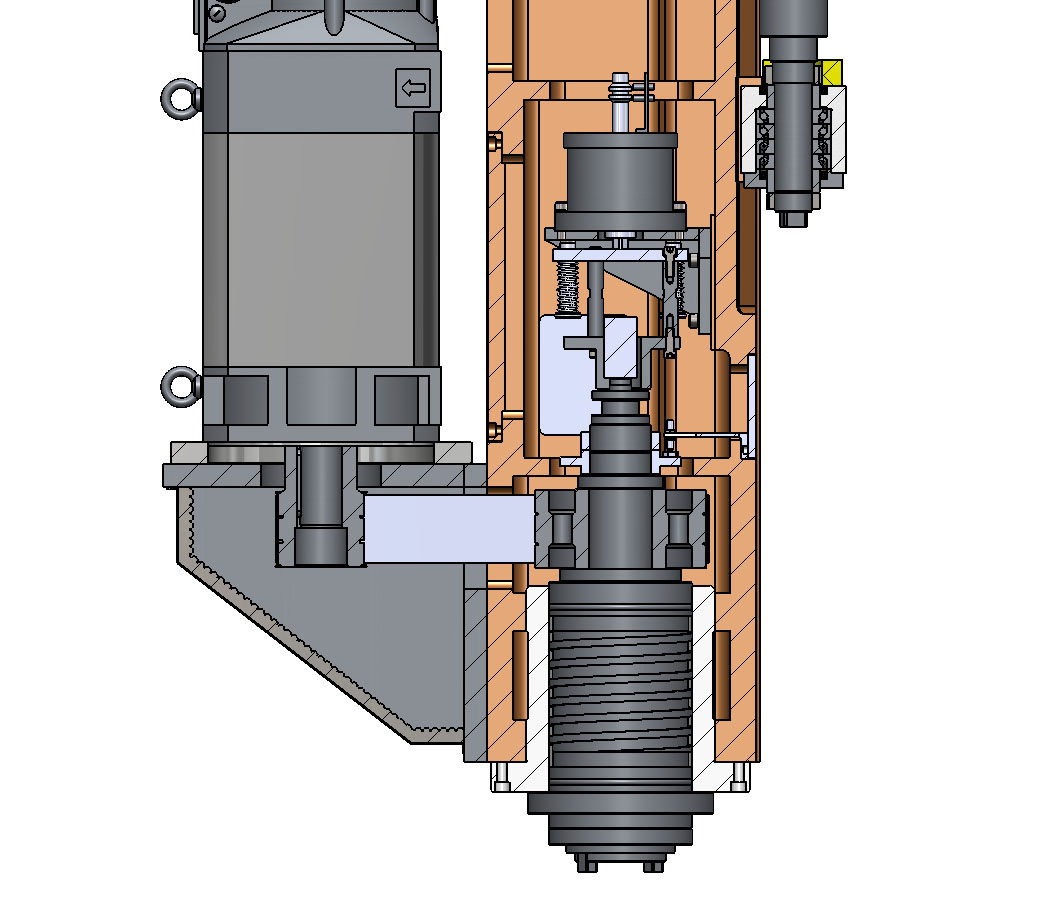

2. Saldhigga sitaha adag ee sare, sitaha wuxuu qaataa sitaha gaarka ah ee boolal sax ah oo sare leh. Dusha sare ee salka ku rakiban ee dheer waxay hubisaa adkaanta axial-ka. Sitaha waxaa horay u adkeeyay laws quful ah, boolalka sitahana waxaa horay loo sii qaboojiyay. Qadarka fidsan waxaa lagu go'aamiyaa iyadoo loo eegayo isbeddelka kulaylka iyo dheereynta boolalka si loo hubiyo in saxnaanta booska ee boolalka sitaha aysan isbeddelin ka dib marka heerkulku kor u kaco.

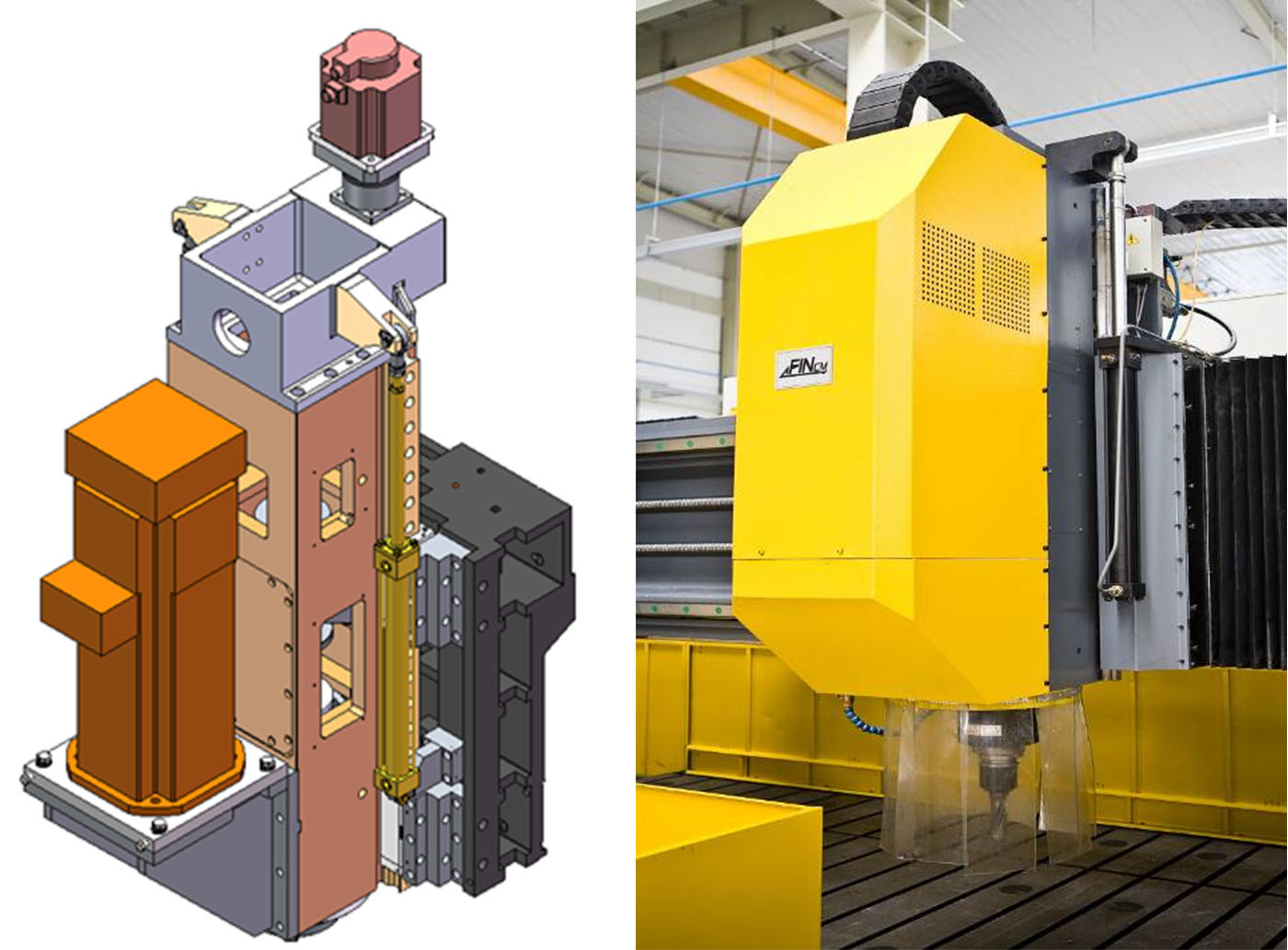

Madaxa korontada qodista iyo shiididda

3. Dhaqdhaqaaqa toosan (dhidibka Z) ee madaxa korontada waxaa hagaya labo hagayaal duuban oo toosan oo lagu hagayo ramka, oo leh saxnaan hagitaan oo wanaagsan, iska caabin gariir sare iyo isku-darka is-jiidjiid hooseeya. Darawalka boolal kubbadda waxaa ku shaqeeya matoor servo ah iyada oo loo marayo yareeye meere oo sax ah, kaas oo leh awood quudin oo sare.

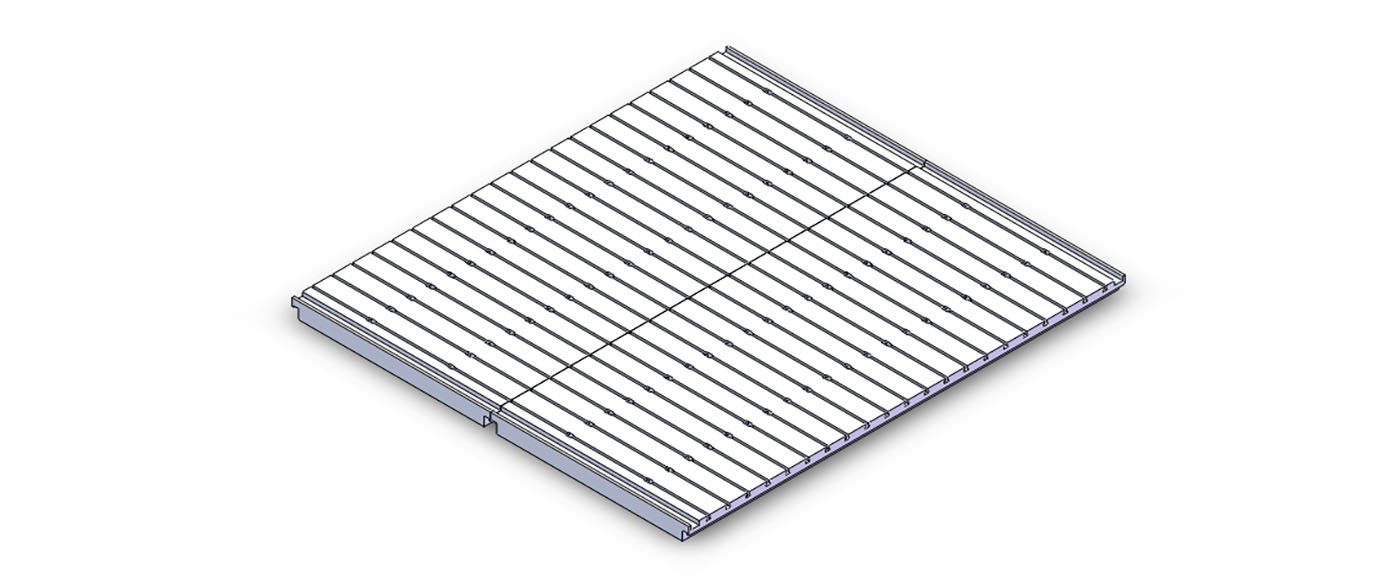

4. Mashiinkani wuxuu qaataa laba qalab oo jajab ah oo silsilad fidsan labada dhinac ee miiska shaqada. Jajabyada birta ah iyo qaboojiyaha ayaa lagu ururiyaa qalabka jajabka, jajabyada birta ahna waxaa loo qaadaa qalabka jajabka, kaas oo aad ugu habboon in laga saaro jajabka; qaboojiyaha dib ayaa loo warshadeeyaa.

5. Mashiinkani wuxuu bixiyaa laba hab oo qaboojin ah - qaboojinta gudaha iyo qaboojinta dibadda, kuwaas oo siiya saliid iyo qaboojin ku filan qalabka iyoagabinta lagu jiro jarista jajabka, taas oo si fiican u damaanad qaadaysadaloolinTayada wax soo saarka. Sanduuqa qaboojinta waxaa ku qalabaysan qaybaha ogaanshaha heerka dareeraha iyo digniinta, cadaadiska qaboojinta ee caadiga ahna waa 2MPa.

dunmiiqa saxda ah

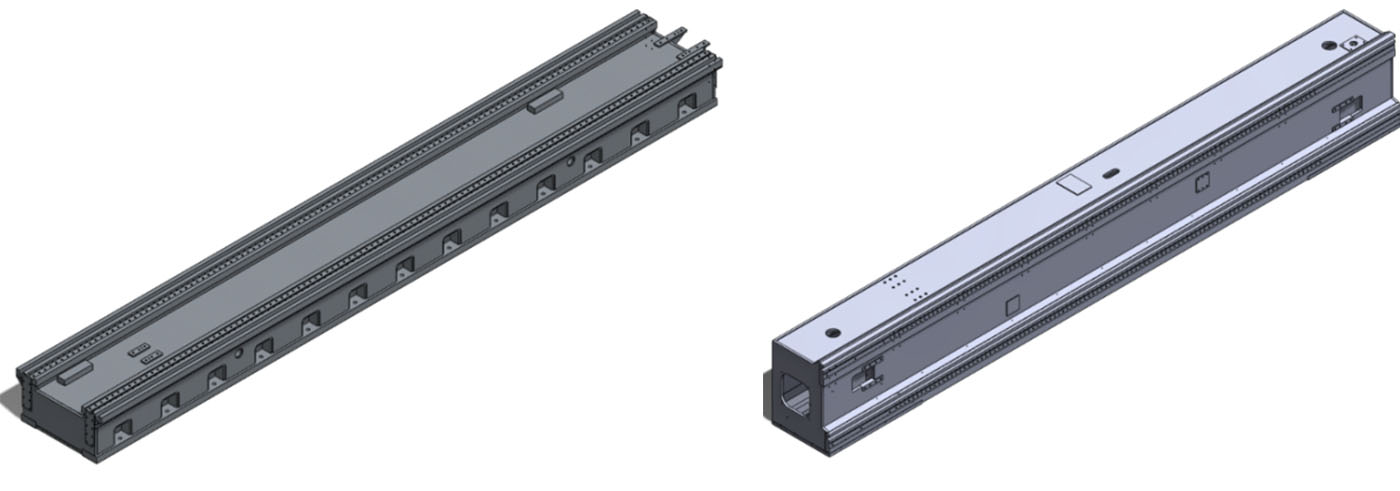

6. Biraha hagaha X-dhidibka ee labada dhinac ee mashiinka waxaa ku qalabaysan daboolo bir ah oo aan miridh lahayn, biraha hagaha Y-dhidibkana waxaa ku qalabaysan daboolo ilaalin dabacsan labada darafba.

Qalabka gudbiyaha jajabka

Qalabka qaboojinta

Qalabka saliidaynta otomaatiga ah

7. Mashiinkan waxa kale oo uu ku qalabaysan yahay qalab sawir-qaadis ah si loo fududeeyo booska saxanka wareegsan.

Nidaamka Siemens CNC

| MAYA. | Magaca | Summada | Waddan |

| 1 | Tareenka hagaha toosan | HIWIN ama PMI | Taiwan, Shiinaha |

| 2 | Nidaamka Xakamaynta CNC | Siemens | Jarmalka |

| 3 | Matoorka Servo iyo darawalka | Siemens | Jarmalka |

| 4 | dunmiiqa saxda ah | KENTURN ama SPINTECH | Taiwan, Shiinaha |

| 5 | Waalka Haydarooliga | YUKEN AMA Justmark | Jabaan |

| 6 | Bamka saliidda | Justmark | Taiwan, Shiinaha |

| 7 | Nidaamka saliidaynta otomaatiga ah | BIJUR AMA HERG | Mareykanka ama Japan |

| 8 | Badhamada, nalalka tilmaamayaasha iyo qaybaha kale ee korontada ee ugu muhiimsan | SCHBEIDER/ABB | Faransiiska / Jarmalka |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga