Mashiinka Qodista Saxanka CNC ee PLM4020 ee Gantry Mobility

(1) Jidhka mashiinka iyo alwaaxa iskutallaabta ah waxay ku jiraan qaab-dhismeed la isku qurxiyey, ka dib markii la daweyn ku filan oo kulayl ah, iyadoo si sax ah loo sameeyay. Miiska shaqada, miiska simbiriirixan ee wareegsan iyo ramka dhammaantood waxay ka samaysan yihiin bir la shubay.

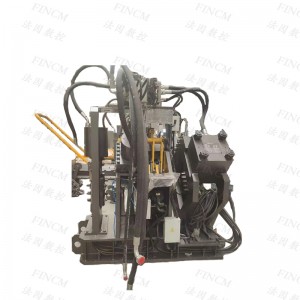

(2) Nidaamka laba-geesoodka ah ee servo ee labada dhinac ee ku yaal dhidibka X wuxuu xaqiijinayaa dhaqdhaqaaqa saxda ah ee barbar socda ee gantry, iyo labajibbaaranaanshaha wanaagsan ee dhidibka Y iyo dhidibka X.

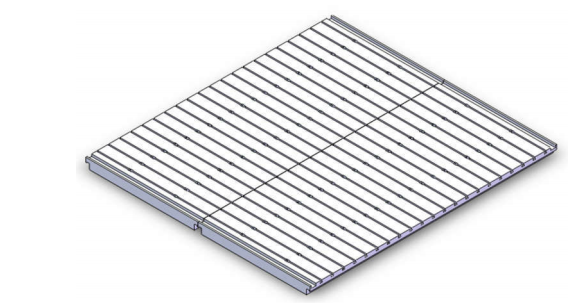

(3) Shaxda shaqadu waxay qaadataa qaab go'an, bir la shubay oo tayo sare leh iyo habka shubista ee horumarsan, oo leh awood qaadis oo weyn.

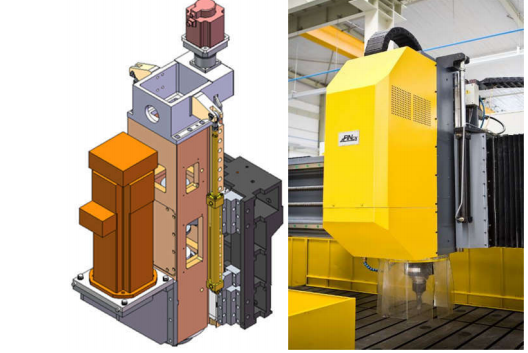

(4) Kursiga sitaha ee adag, sitaha wuxuu qaataa habka rakibidda gadaal-ilaa-gadaal, sitaha gaarka ah oo leh boolal sax ah oo sare.

(5) Dhaqdhaqaaqa toosan (dhidibka Z) ee madaxa korontada waxaa hagaya lammaane hagayaal toosan oo duuban oo ku diyaarsan labada dhinac ee ramka, kaas oo leh saxnaan wanaagsan, iska caabin gariir sare iyo isku-dhafka is-jiidjiid hooseeya.

(6) Sanduuqa korontada qodista waxaa iska leh nooca isgoyska saxda ah ee adag, kaas oo qaata isgoyska qaboojinta gudaha ee Taiwan BT50. Godka isgoyska wuxuu leeyahay qalab nadiifin ah, wuxuuna isticmaali karaa qodista qaboojinta gudaha ee carbide ee sibidhka leh, oo leh saxnaan sare. Isgoyska waxaa ku shaqeeya matoorka servo ee awoodda sare leh iyada oo loo marayo suunka isku-dhafan, saamiga dhimista waa 2.0, xawaaraha isgoyska waa 30~3000r/daqiiqo, xawaarahana waa ballaaran yahay.

(7) Mashiinku wuxuu qaataa laba qalab oo jajab ah oo silsilad fidsan labada dhinac ee miiska shaqada. Jajabyada birta ah iyo qaboojiyaha waxaa lagu ururiyaa qalabka jajabka. Jajabyada birta ah waxaa loo qaadaa qalabka jajabka, kaas oo aad ugu habboon in laga saaro jajabyada. Qaboojiyaha dib ayaa loo warshadeeyaa.

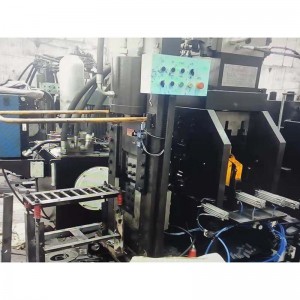

(8) Mashiinku wuxuu bixiyaa laba nooc oo habab qaboojin ah - qaboojinta gudaha iyo qaboojinta dibadda. Bamka biyaha ee cadaadiska sare leh waxaa loo isticmaalaa in lagu bixiyo qaboojinta loo baahan yahay qaboojinta gudaha, iyadoo leh cadaadis sare iyo socod ballaaran.

(9) Mashiinku wuxuu ku qalabaysan yahay nidaam saliidayn oo otomaatig ah, kaas oo saliidda saliidaynta ku shubaya baloogga toosan ee hagaha, lowska boolal-ka ee isku-xidhka iyo boolal-rogidda qayb kasta si joogto ah si loo fuliyo saliidaynta ugu filan uguna kalsoonida badan.

(10) Biraha hagaha X-dhidibka ee labada dhinac ee mashiinka waxaa ku qalabaysan daboolo ilaalin bir ah oo aan miridh lahayn, biraha hagaha Y-dhidibkana waxaa lagu rakibay daboolo ilaalin dabacsan.

(11) Qalabka mashiinka waxaa sidoo kale ku qalabaysan qalab sawir-qaade ah si loo fududeeyo booska shaqooyinka wareegsan.

(12) Qalabka mashiinka waxaa loogu talagalay oo lagu rakibay qalab badbaado oo dhammaystiran. Laamiga gangry-ga ah waxaa ku qalabaysan goob socod, difaac, iyo jaranjaro fuulitaan ah oo dhinaca tiirka ah si loo hubiyo badbaadada shaqaalaha hawlgalka iyo dayactirka. Dabool jilicsan oo PVC ah ayaa lagu rakibay hareeraha usha weyn.

(13) Nidaamka CNC wuxuu ku qalabaysan yahay Siemens 808D ama Fagor 8055, kaas oo leh shaqooyin awood badan. Is-dhexgalka hawlgalka wuxuu leeyahay shaqooyinka wadahadalka mashiinka-man, magdhowga khaladaadka iyo digniinta otomaatiga ah. Nidaamku wuxuu ku qalabaysan yahay giraangiraha gacanta ee elektaroonigga ah, kaas oo si fudud loo shaqayn karo. Iyada oo lagu qalabeeyay kombuyuutar la qaadi karo, barnaamijka otomaatiga ah ee CAD-CAM ayaa la hirgelin karaa ka dib marka la rakibo barnaamijka kumbuyuutarka sare.

| Shay | Magaca | Qiimaha |

|---|---|---|

| Cabbirka ugu Badan ee Saxanka | L x W | 4000 × 2000 mm |

| Cabbirka ugu Badan ee Saxanka | Dhexroorka | Φ2000mm |

| Cabbirka ugu Badan ee Saxanka | Dhumucda ugu badan | 200 mm |

| Miiska Shaqada | Ballaca booska T | 28 mm (caadi ah) |

| Miiska Shaqada | Cabbirka miiska shaqada | 4500x2000mm (LxW) |

| Miiska Shaqada | Miisaanka la rarayo | 3 tan/㎡ |

| Isgoyska Qodista | Ballaca Qodista ugu badan | Φ60 mm |

| Isgoyska Qodista | Dhexroorka ugu Badan ee Taabashada | M30 |

| Isgoyska Qodista | Dhererka Usha qodista ee isgoyska iyo dhexroorka godka | ≤10 |

| Isgoyska Qodista | RPM | 30~3000 r/daqiiqo |

| Isgoyska Qodista | Nooca cajaladda isbaarada | BT50 |

| Isgoyska Qodista | Awoodda matoorka dunmiiqa | 22kW |

| Isgoyska Qodista | Wareegga ugu badan (n≤750r/daqiiqo) | 280Nm |

| Isgoyska Qodista | Masaafada u dhaxaysa dusha sare ee Spindle ilaa miiska shaqada | 280~780 mm (la hagaajin karo sida ku cad dhumucda walxaha) |

| Dhaqdhaqaaqa Longitudinal Gantry (X Axis) | Ugu Badan Safarka | 4000 mm |

| Dhaqdhaqaaqa Longitudinal Gantry (X Axis) | Xawaaraha dhaqdhaqaaqa ee ku teedsan dhidibka X | 0 ~ 10m/daqiiqo |

| Dhaqdhaqaaqa Longitudinal Gantry (X Axis) | Awoodda matoorka adeegga ee dhidibka X | 2 × 2.5kW |

| Dhaqdhaqaaqa Kala-guurka Spindle (Dhinaca Y) | Ugu Badan Safarka | 2000mm |

| Dhaqdhaqaaqa Kala-guurka Spindle (Dhinaca Y) | Xawaaraha dhaqdhaqaaqa ee ku teedsan dhidibka Y | 0 ~ 10m/daqiiqo |

| Dhaqdhaqaaqa Kala-guurka Spindle (Dhinaca Y) | Awoodda matoorka adeegga ee dhidibka Y | 1.5kW |

| Dhaqdhaqaaqa Quudinta Spindle (Dhinaca Z) | Ugu Badan Safarka | 500 mm |

| Dhaqdhaqaaqa Quudinta Spindle (Dhinaca Z) | Xawaaraha quudinta ee dhidibka Z | 0~5m/daqiiqo |

| Dhaqdhaqaaqa Quudinta Spindle (Dhinaca Z) | Awoodda matoorka adeegga ee dhidibka Z | 2kW |

| Saxnaanta booska | dhidibka X, dhidibka Y | 0.08/0.05mm/safar buuxa |

| Saxnaanta booska lagu celin karo | dhidibka X, dhidibka Y | 0.04/0.025mm/safar buuxa |

| Nidaamka Haydarooliga | Heerka cadaadiska/socodka bamka haydarooliga | 15MPa / 25L/daqiiqo |

| Nidaamka Haydarooliga | Awoodda matoorka bamka Haydarooliga | 3.0kW |

| Nidaamka sambabbada | Cadaadiska hawada ee la cadaadiyay | 0.5 MPa |

| Nidaamka qaboojinta iyo ka saarista qashinka | Nooca ka saarista qashinka | Silsilad saxan |

| Nidaamka qaboojinta iyo ka saarista qashinka | Tirooyinka ka saarista qashinka | 2 |

| Nidaamka qaboojinta iyo ka saarista qashinka | Xawaaraha ka saarista qashinka | 1m/daqiiqad |

| Nidaamka qaboojinta iyo ka saarista qashinka | Awoodda Matoorka | 2 × 0.75kW |

| Nidaamka qaboojinta iyo ka saarista qashinka | Habka qaboojinta | Qaboojinta gudaha + Qaboojinta dibadda |

| Nidaamka qaboojinta iyo ka saarista qashinka | Cadaadiska ugu badan | 2MPa |

| Nidaamka qaboojinta iyo ka saarista qashinka | Heerka ugu badan ee socodka | 50L/daqiiqad |

| Nidaamka elektaroonigga ah | Nidaamka xakamaynta CNC | Siemens 808D |

| Nidaamka elektaroonigga ah | Lambarka Dhidibka CNC. | 4 |

| Nidaamka elektaroonigga ah | Awood guud | Qiyaastii 35kW |

| Cabbirka Guud | L × W × H | Qiyaastii 10 × 7 × 3m |

| Maya. | Magaca | Summada | Waddan |

|---|---|---|---|

| 1 | Tareenka hagaha toosan ee wareega | Hiwin | Shiinaha Taiwan |

| 2 | Nidaamka xakamaynta CNC | Siemens/ Fagor | Jarmalka/Isbaanishka |

| 3 | Quudinta matoorka servo iyo darawalka servo | Siemens/Panasonic | Jarmalka/Japan |

| 4 | Isteerinka saxda ah | Spintech/Kenturn | Shiinaha Taiwan |

| 5 | Waalka Haydarooliga | Yuken/Justmark | Jabaan/Shiinaha Taiwan |

| 6 | Bamka saliidda | Justmark | Shiinaha Taiwan |

| 7 | Nidaamka saliidaynta otomaatiga ah | Herg/BIJUR | Jabaan/Mareykan |

| 8 | Badhan, Tilmaame, qaybaha elektarooniga ah ee danab hooseeya | ABB/Schneider | Jarmalka/Faransiiska |

| Maya. | Magaca | Cabbirka | Tirada. |

|---|---|---|---|

| 1 | Soo-saare gees indhaha ah | 1 gabal | |

| 2 | Fure gudaha ah oo lix geesle ah | 1 qaybood | |

| 3 | Qalabka haystaha iyo jiidista stud | Φ40-BT50 | 1 gabal |

| 4 | Qalabka haystaha iyo jiidista stud | Φ20-BT50 | 1 gabal |

| 5 | Rinjiga dheeraadka ah | - | 2 keg |

1. Korontada: 3 waji 5 khad 380+10%V 50+1HZ

2. Cadaadiska hawada ee la cadaadiyay: 0.5MPa

3. Heerkulka: 0-40℃

4. Qoyaan: ≤75%