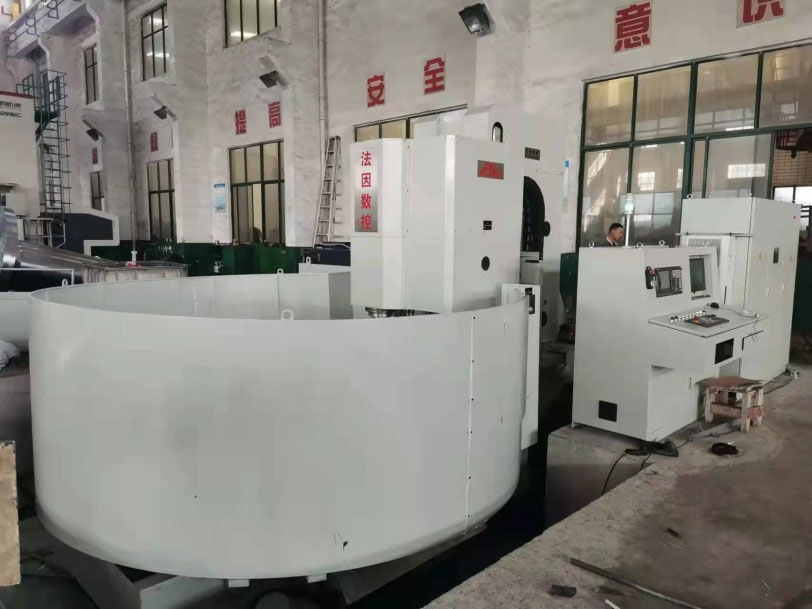

Mashiinka Qodista CNC ee Taxanaha PM (Mashiinka Rotary)

| NO | Shay | Halbeegga | |||

| PM20A | PM25B | PM30B | |||

| 1 | Cabbirka ugu badan ee walxaha | Cabbirka habaynta | Φ800~Φ2000mm | φ1000~φ2500mm | φ1300~φ3000mm |

| Ugu badnaanagabdhumucdiisuna waa | 300 mm | ||||

| 2 | Miiska wareega (C-dhidibka) cadaadis taagan | Dhexroorka miiska wareega | 2000mm | Ф2500 mm | Ф3000 mm |

| Ballaca T-godka | 36 mm | ||||

| Lboolal qaada | 3T/m | 30T | 40T | ||

| Deji cutubka ugu yar ee tusmada | 0.001° | ||||

| Xawaaraha wareegga dhidibka C | 0-1r/daqiiqo | ||||

| Saxnaanta booska dhidibka C | 8"(Habayn gaar ah) | ||||

| Saxnaanta booska ku celcelinta ee dhidibka C-dhidibka | 4"(Habayn gaar ah) | ||||

| Miisaanka | 17Tan | 17Tan | 19 Tan | ||

| 3 | Madaxa madaxa | Dhexroorka ugu badan ee ceelka | Φ96mm | Φ60 mm(Laydhka Karbidka) | Φ70 mm(Laydhka Karbidka) |

| Dhexroorka ugu badan ee tuubada | M30 | M45 | M56 | ||

| Xawaaraha ugu badan ee dunmiiqa | 3000r/daqiiqo | 2000r/daqiiqo | |||

| Isgoyska | BT50 | ||||

| Awoodda matoorka dunmiiqa | 45KW | 30/41kW | 30/45kW | ||

| Xuddunta ugu badan ee wareegga ≤ 250r / daqiiqo | 1140/1560Nm | ||||

| Sanduuqa doorsoomaha ah | 1:1.2/1:4.8 | ||||

| Masaafada u dhaxaysa wejiga dhammaadka dunduleelka iyo miiska wareega | 400-900mm | 400-1050mm | |||

| Masaafada u dhaxaysa dhidibka isgoyska ilaa xarunta miiska wareega | 500-1700mm | 650-1850mm | |||

| 4 | Nidaamka Haydarooliga | Cadaadiska / socodka bamka haydarooliga | 6.5Mpa/25L/daqiiqo | ||

| Awoodda mootada ee bamka haydarooliga | 3KW | ||||

| 5 | Nidaamka korontada | Nidaamka xakamaynta tirooyinka | Siemens 828D | ||

| Tirada faasaska CNC | 3+1 | 3+1 | 3+1 | ||

| Awoodda guud ee matoorka | ku saabsan75kW | qiyaastii 50kW | qiyaastii 70kW | ||

| 6 | Cabbirka mashiinka (L*W*H) | Aqiyaastii 5.8*4.2*5m | qiyaastii 6.3*4.7*5m | ||

| 7 | Magudaha mamiisaanka Shiinaha | ≥17Tan | Mashiinka: 20T Hydrostatic turret:17T | Mashiin: 20T Munaaradda Hydrostatic:19T | |

1. Mashiinku wuxuu inta badan ka kooban yahay sariir iyo silidhidh dherer leh, silidhidh gant iyo silidhidh isdhaafsan, isku-xidhka isku-xidhka otomaatiga ah, madaxa qodista ram-ka toosan, nidaamka haydarooliga, nidaamka qaboojinta, nidaamka korontada, saliidaynta otomaatiga ah iyo qaybo kale.

2. Jihada Z-da waxaa si toosan loogu rakibay slide-ka jihada Y, kaas oo ay hagto lammaanayaasha hagaha duubista toosan ee labada dhinac ee wanka, oo ay wadaan lammaanayaasha boolal ee hogaanka oo uu wado matoorka servo, oo ay dheellitiraan dhululubada haydarooliga.

3. Silsilad hawo-mareenka ah oo nooca toosan ee quudinta ram-ka CNC ayaa lagu rakibay saxanka slide-ka ee dhaqdhaqaaqa jihada Y ee gantry-ga dhaqdhaqaaqa si loogu dheellitiro. Madaxa qodista wuxuu qaataa matoorka beddelka soo noqnoqda ee gaarka ah ee isgoyska wuxuuna ku wadaa isgoyska suunka isku-xidhka ah. Waxay leedahay wareeg xawaare hoose oo weyn waxayna qaadi kartaa culays goyn culus. Waxay sidoo kale ku habboon tahay farsamaynta xawaaraha sare ee qalabka carbide-ka.

4. Isgoyska saxda ah ee Taiwan (qaboojinta gudaha) ayaa loo isticmaalay isgoyska qodista mashiinkan. Godka isgoyska BT50 wuxuu leeyahay farsamo iswada oo ah ubax balanbaalis ah.

5. Qalabka isku xidhka otomaatiga ah waxaa loo isticmaalaa in lagu xiro walxaha wareegsan si toos ah, xoogga isku xidhkana si fudud ayaa loo hagaajin karaa. Qalabka isku xidhka ayaa laga soocaa sariirta si loo helo isku xidhka otomaatiga ah ee degdega ah iyo hawlgal la isku halayn karo.

6. Biraha hagaha X-dhidibka ee labada dhinac ee mashiinka waxaa lagu rakibay dabool ilaalin bir ah oo aan miridh lahayn, biraha hagaha Y-dhidibkana waxaa lagu rakibay dabool ilaalin dabacsan labada darafba, oo leh shaqo xaddidan oo jilicsan.

7. Mashiinku wuxuu leeyahay qalab loogu talagalay in lagu qaado jajabyada silsiladda fidsan, sanduuqa qabashada jajabku waa nooca rogrogmada, iyo nidaamka qaboojinta oo leh shaandho warqad ah, qaboojiyahana waa la dib u warshadeeyaa.

8. Nidaamka CNC ee mashiinkan wuxuu qaataa Isbaanish FAGOR8055, oo leh giraangiraha gacanta elektarooniga ah, shaqo awood leh iyo hawlgal fudud. Waxa uu ku qalabaysan yahay kombiyuutar sare iyo interface RS232, waxana uu leeyahay hawlaha habaynta horudhaca iyo dib u eegista. Interface-ka hawlgalka waxa uu leeyahay shaqooyinka wadahadalka mashiinka aadanaha, magdhowga khaladaadka iyo digniinta otomaatiga ah.

| NO | Magaca | Summada | Waddan |

| 1 | Hagaha toosan ee duuban | HIWIN | Taiwan, Shiinaha |

| 2 | Boorsooyin kubbadeed | NEFF/IF | Jarmalka |

| 3 | Miiska wareega ee Ф 2500 (cadaadis taagan) | Kooxda Mashiinka Qalabka JIER | Shiinaha |

| 4 | Nidaamka xakamaynta tirooyinka | Siemens 828D | Jarmalka |

| 5 | Quudinta matoorka servo iyo darawalka | Siemens | Jarmalka |

| 6 | Matoorka ugu weyn | Siemens | Jarmalka |

| 7 | Mastar shabagga | FAGOR | Isbayn |

| 8 | Spindle | Kenturn | Taiwan, Shiinaha |

| 9 | Waalka Haydarooliga | ATOS | Talyaaniga |

| 10 | Bamka saliidda | Justmark | Taiwan, Shiinaha |

| 11 | Nidaamka saliidaynta otomaatiga ah | BIJUR | Mareykanka |

| 12 | Bamka qaboojinta | Fengchao Pumps | Shiinaha |

| 13 | Badhan, nalka tilmaame iyo qaybaha kale ee korontada ugu muhiimsan | Schneider | Faransiiska |

| 14 | Tkiiska wareejinta | GTP | Taiwan, Shiinaha |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga