Mashiinka Feeraha ee PPL1255 CNC ee loogu talagalay Taarikada loo isticmaalo Gawaarida Xamuulka qaada

| MAYA. | MAGACA | QEEXITAANADA | |

| 1 | Qalabka saxanka ee gaariga xamuulka qaada/looriga xamuulka qaada | Saxancabbir | Dhererka:4000~12000mm |

| Ballaca:250~550mm | |||

| Dhumucda:4~12mm | |||

| Miisaanka:≤600kg | |||

| Kala duwanaanshaha dhexroorka feerka:φ9~φ60mm | |||

| 2 | Mashiinka feeraha CNC (dhidibka Y) | Cadaadis Magaceed | 1200kN |

| Tirada feerka la jaray | 25 | ||

| Dhidibka Yistaroog | qiyaastii 630mm | ||

| Xariiqda Y xawaaraha ugu badan. | 30m/daqiiqo | ||

| Awoodda matoorka adeegga | 11kW | ||

| Baloogistaroog | 180mm | ||

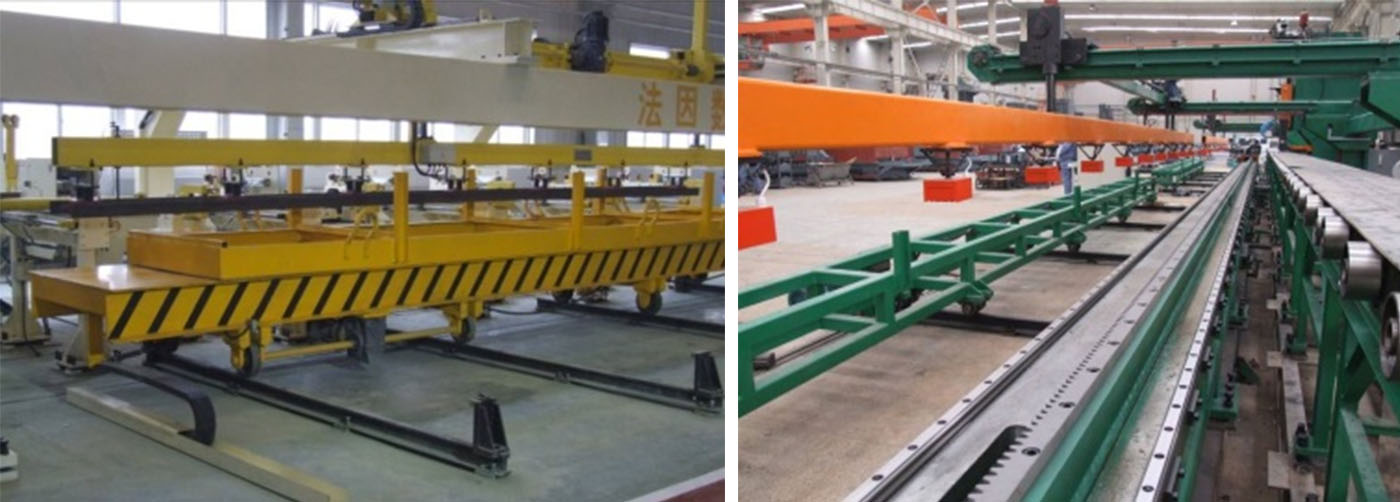

| 3 | Cutubka rarista birlabta | Dhaqdhaqaaq heer sare ahistaroog | qiyaastii 1800mm |

| Dhaqdhaqaaq toosanistaroog | Qiyaastii 500mm | ||

| Awoodda matoorka heerka | 0.75kW | ||

| Awoodda matoorka toosan | 2.2k | ||

| Tirada birlabta | 10 xabbo | ||

| 4 | Cutubka quudinta CNC (dhidibka X) | Safarka X dhidibka | Qiyaastii 14400mm |

| Xawaaraha ugu badan ee dhidibka X | 40m/daqiiqo | ||

| Awoodda matoorka adeegga | 5.5kW | ||

| Tirada xakamaynta haydarooliga | 7 xabbo | ||

| Xoogga qabsashada | 20kN | ||

| Safarka furitaanka ee qabsashada | 50mm | ||

| Safarka ballaarinta qabsashada | Dhererka 165mm | ||

| 5 | Qaadaha quudinta | Dhererka quudinta | 800mm |

| Dhererka quudinta | ≤13000mm | ||

| Dhererka quudinta dibadda | ≤13000mm | ||

| 6 | Cutubka riixaha | Tiradaiyada | 6 kooxood |

| Safar | qiyaastii 450mm | ||

| Riix | 900N/ koox | ||

| 7 | Enidaamka korontada | Awood guud | qiyaastii 85kW |

| 8 | Khadka wax soo saarka | Dhererka x ballaca x dhererka | qiyaastii 27000 × 8500 × 3400mm |

| Wadarta miisaanka | qiyaastii 44000kg | ||

1. Riixista dhinaca, cabbirka ballaca xaashida birta ah iyo habka dhexe ee otomaatiga ah: Hababkani waxay leeyihiin tignoolajiyad shati leh oo sax ah cabbir sare leh waxayna ka mid yihiin faa'iidooyinka si fudud loogu rakibo loona adeego, xaashida birta ah waxaa lagu dhejin karaa dhinaca xaashida birta ah.

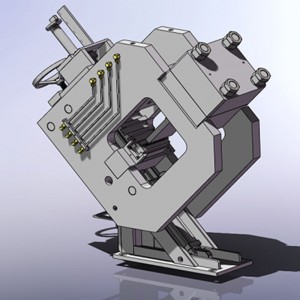

Qaybta feerka ugu weyn: Jirka mishiinku waa qaab furan oo nooca C ah, oo si fudud loo adeegi karo. Habka riixista qalabka qaboojinta ee haydarooliga iyo habka dejinta feerka ayaa si wada jir ah u shaqeeya si looga fogaado baloogga xaashida birta ah, taasoo hubinaysa badbaadada mishiinka.

3. Habka feer-beddelka degdegga ah iyo feerka: Habkani waa mid shati haysta oo feeraya waxaana lagu beddeli karaa waqti aad u gaaban, mid gooni ah ama dhammaan qalabka markiiba.

| NO. | Magaca | Summada | Waddan |

| 1 | Dhululubo laba jillaab ah | SMC/FESTO | Jabaan / Jarmalka |

| 2 | Dhululubo bacaha hawada ah | FESTO | Jarmalka |

| 3 | waalka solenoid iyo badhanka cadaadiska, iwm.. | SMC/FESTO | Jabaan / Jarmalka |

| 4 | Dhululubo feer oo weyn | Shiinaha | |

| 5 | Qaybaha ugu muhiimsan ee haydarooliga | ATOS | Talyaaniga |

| 6 | tareenka hagaha toosan | HIWIN/PMI | Taiwan, Shiinaha(Dhidibka Y) |

| 7 | tareenka hagaha toosan | HIWIN/PMI | Taiwan, Shiinaha(Dhidibka X) |

| 8 | Xidhiidhka dabacsan ee aan lahayn dib-u-dhac | KTR | Jarmalka |

| 9 | Qalab yareeya, qalabka baabi'inta nadiifinta iyo raafka | ATLANTA | Jarmalka(Dhidibka X) |

| 10 | Silsilad jiidid | Igus | Jarmalka |

| 11 | Matoorka Servo iyo darawalka | Yaskawa | Jabaan |

| 12 | Beddelaha soo noqnoqda | Rexroth/Siemens | Jarmalka |

| 13 | CPU iyo modules kala duwan | Mitsubishi | Jabaan |

| 14 | Shaashadda taabashada | Mitsubishi | Jabaan |

| 15 | Qalabka saliidaynta otomaatiga ah | Herg | Jabaan(Saliid khafiif ah) |

| 16 | Kombiyuutar | Lenovo | Shiinaha |

| 17 | Qaboojiyaha saliidda | Tofly | Shiinaha |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga