PUL14 CNC U Channel iyo Mashiinka Calaamadaynta Feeraha ee Flat Bar

| Shaqeynaya agabmasaafada | 80x43x5~140x60x8mm(Kanaalka U) |

| 40x3-80x8mm(Baar siman) | |

| Alaabnooca | Q235 |

| Feer xoog magaceed ah | 950KN |

| Dhexroorka ugu badan ee feerkar | φ26mm(Wareeggod) |

| φ22x60mm(Ubax qaabaysangod) | |

| Tirada feedhkajagooyinka | 3 |

| Calaamadaynta xoogga magacaaban | 630KN |

| Tiradacalaamadayntakooxo | 4 |

| Tiradacalaamadayntakoox kasta | 10 |

| Jilaacabbirka | 14x10x19mm |

| Xoogga xiirashada magacaaban | 750KN(bir xariijin ah) |

| 1000KN(Kanaal-birta) | |

| Joojiqaab | Keli ahjarista daabyada |

| Ugu badnaanwalxo cayriin ahdhererth | 9m |

| Ugu badnaan la dhammeeyayagabdhererka | 3m |

| Saxnaanta mashiinka | Buuxi shuruudaha GB / T 2694-2010 |

| Habka qaboojinta | qaboojinta biyaha |

| Awoodda guud ee qalabka | 33KW |

| Cabbirrada mashiinka | 27x9x2.2m |

| Miisaanka saafiga ah | Qiyaastii 14tan |

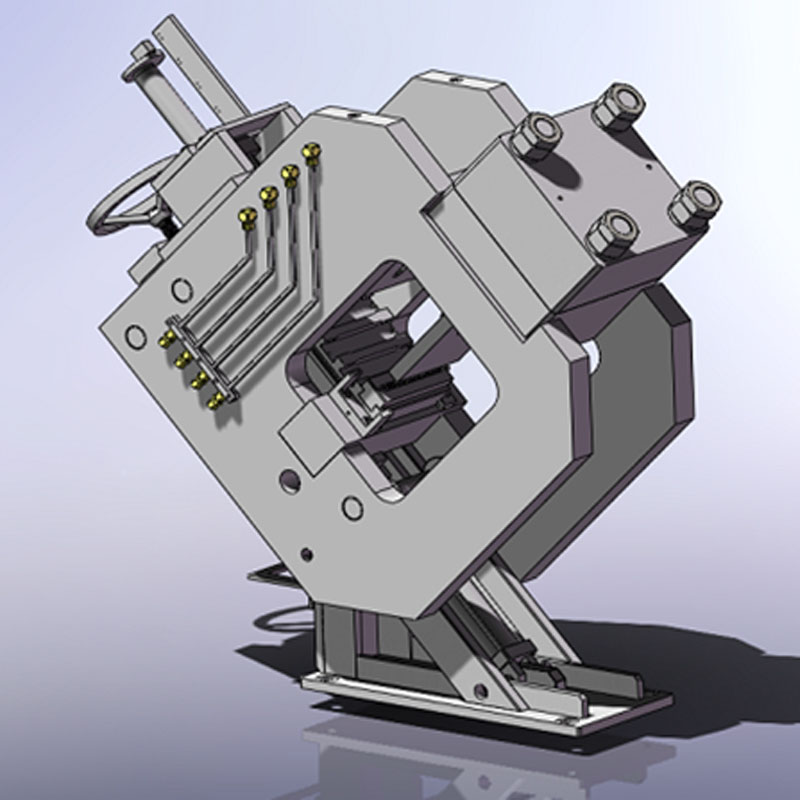

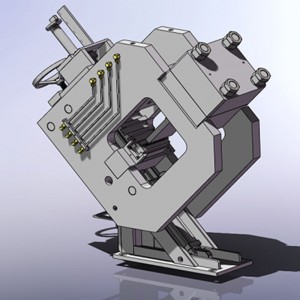

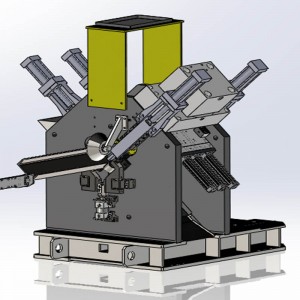

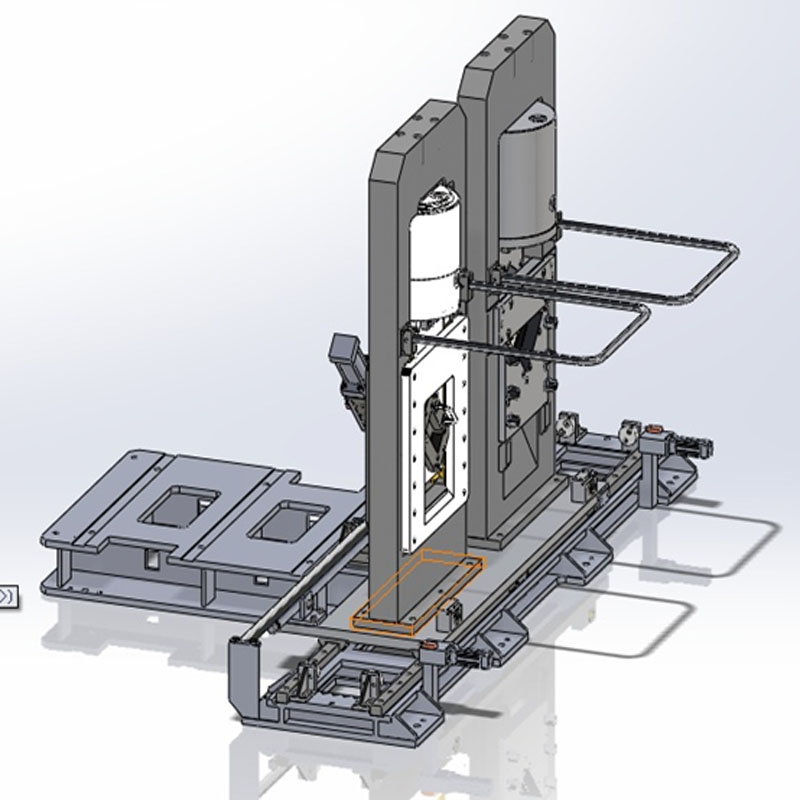

1. Mashiinka ugu weyn wuxuu ka kooban yahay cutub calaamadeyn ah, cutub feer ah iyo cutub xiiraya

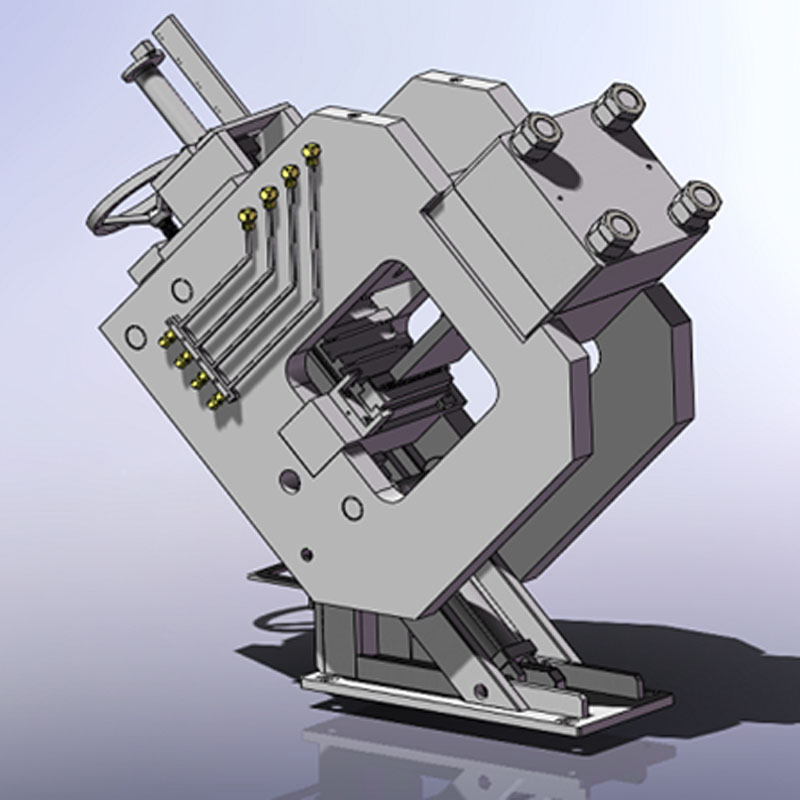

① Qaybta calaamadaynta waxay qaadataa jir xiran. Iyada oo leh afar cajaladood oo la isku beddeli karo, cajalad kastaa waxay qaadi kartaa 10 xaraf; Birta kanaalka waxaa lagu calaamadeyn karaa oo keliya shabakadda.

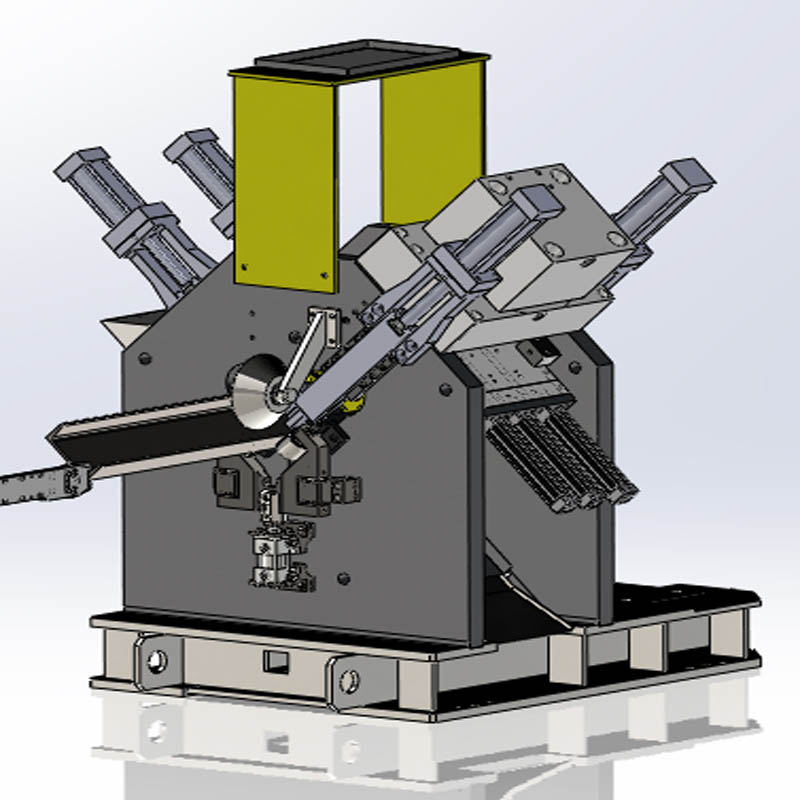

② Qaybta feerka waxay qaadataa jir xiran, kaas oo ku dhejin kara saddex god oo leh dhexroor kala duwan (god wareegsan iyo god oval ah) agabka.

③ Qalabka jarista wuxuu ka kooban yahay laba qalab jarista: jarista baarka fidsan iyo jarista kanaalka. Habka jarista daabyada hal mar ayaa la qaataa si loo hubiyo qaybta jarista ee nadiifka ah, hagaajinta habboon ee farqiga jarista iyo keydinta agabka.

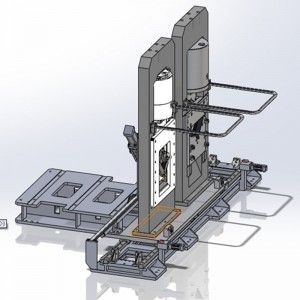

2. Maaddada waxaa lagu xiraa qabsato neef ah waxayna si dhakhso ah ugu dhaqaaqdaa booska. Maaddada waxaa wada matoorka servo waxaana wada raafka geerka, iyadoo leh saxnaan meelayn sare.

3. Qalabka gudbiyaha ee isdhaafka ah wuxuu ka kooban yahay afar silsiladood oo leh baloogyo wareegaya iyo jir qaab-dhismeed, silsiladdana waxaa wada matoorka iyada oo loo marayo qalab yareeya.

4. Qalabka wax soo saara wuxuu ka kooban yahay qalab qaada iyo silinda. Marka walxaha la dhammeeyay ay ka soo baxaan qaybta ugu weyn ee mashiinka, waa la wareejiyaa oo laga soo diraa khadka wax soo saarka.

5. Mashiinku wuxuu leeyahay saddex faas oo CNC ah: dhaqdhaqaaqa iyo meelaynta gaariga quudinta iyo dhaqdhaqaaqa kor iyo hoos iyo meelaynta qalabka feerka.

6. Barnaamijyada kombiyuutarku waa kuwo fudud, waxayna soo bandhigi karaan sawirada agabka iyo cabbirka isku-dhafka booska godka, taas oo ku habboon kormeerka. Maareynta kombiyuutarrada sare ayaa la qaataa, taas oo si weyn u sahlaysa kaydinta iyo wicitaanka barnaamijka; Bandhigga Sawir-gacmeedka; Baaritaanka cilladaha iyo isgaarsiinta fog.

7. Habka qaboojinta ee xirmada korontada ee haydarooliga: qaboojinta biyaha ama qaboojinta hawada (ikhtiyaar).

| NO | Magaca | Summada | Waddan |

| 1 | Matoorka adeegga AC | Delta/Schneider | Taiwan, Shiinaha / Faransiiska |

| 2 | PLC | Yokogawa/ Schneider | Jabaan / Faransiiska |

| 3 | Qaybta gelinta | Yokogawa/ Schneider | Jabaan / Faransiiska |

| 4 | moduleka wax soo saarka | Yokogawa/ Schneider | Jabaan / Faransiiska |

| 5 | Qaybta meelaynta | Yokogawa/ Schneider | Jabaan / Faransiiska |

| 6 | Xiriiriyaha | Siemens | Jarmalka |

| 7 | Beddelaha mootada | Siemens | Jarmalka |

| 8 | Silsilad taageero ah | Kabel | Jarmalka |

| 9 | waalka dejinta elektromagnetic | ATOS | Talyaaniga |

| 10 | Waalka gargaarka | ATOS | Talyaaniga |

| 11 | Waalka jihada ee korontada ku shaqeeya | JUSTMARK | Taiwan, Shiinaha |

| 12 | Saxanka Jiidista | AirTAC | Taiwan, Shiinaha |

| 13 | Waalka hawada | AirTAC | Taiwan, Shiinaha |

| 14 | Silsilad | SMC | Jabaan |

| 15 | Duplex | SMC | Jabaan |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga