Mashiinka Qodista CNC ee RDL25A

| Qeexitaanka tareenka la warshadeeyay | Nooca tareenka | 43Kg/m,50Kg/m,60Kg/m,75Kg/m,UIC54,UIC60 |

| ATqaabka tareenka | 50AT,60 AT,UIC60D40 | |

| Birta garabka ee qaybta gaarka ah | 60TY | |

| Cabbirka tareenka | Ballaca hoose | 114-152mm |

| Dhererka tareenka | 128-192mm | |

| Shabakaddadhumucdiisuna waa | 14.5-44mm | |

| Dhererka tareenka (ka dib marka la jarayo) | 6-25m | |

| Nooca walxaha tareenka | U71Mn σb≥90Kg/mm² HB250PD3 σb≥98Kg/mm² HB290-310 | |

| Qodistamadaxa | Dhexroorka | φ20~φ33 |

| Kala duwanaanshaha dhererka | 3D~4D | |

| Shuruudaha ka baaraandegidda | Kala duwanaanshaha dhererka godka | 35~100mm |

| Holedhexroor tirooyinbir kasta oo ku taal | 1~4 noocyada | |

| La ogol yahaydulqaadkala fogaanshaha godadka ku xiga | ±0.3mm | |

| La ogol yahaydulqaadinta u dhaxaysa wejiga dhammaadka tareenka iyo masaafada ugu dhow ee godka | ±0.5mm | |

| La ogol yahaydulqaadmasaafada ugu fog ee godka tareenka | ±0.5mm | |

| La ogol yahaydulqaadeedhexroorka godkacabbirka | 0~+0.3mm | |

| Qalafsanaanta derbiga godka | Ra12.5 | |

| La ogol yahaydulqaaddhererka bartamaha godka (laga bilaabo salka tareenka) | ±0.3mm | |

| Tiirka moobaylka (oo ay ku jiraan qodista)ingsanduuqa korontada) | Tirada | 1 qaybood |

| Godka dunmiiqa | BT50 | |

| Kala duwanaanshaha xawaaraha isbaarada (xawaaraha aan tallaabo lahayn) | 10~3200r/daqiiqo | |

| Awoodda matoorka Spindle Servo | 37kW | |

| Safarka sibidhka toosan (dhidibka Y) | 800mm | |

| Awoodda matoorka servo-ga ee sibidhka toosan (dhidibka Y) | 3.1kw | |

| Quudinta quudinta ee toosan (dhidibka Z) | 350mm | |

| Quudinta qodista toosan (dhidibka Z) awoodda matoorka servo | 3.1kw | |

| Istaraatiijiyada safarka ee toosan ee tiirka (dhidibka X) | 25m | |

| Dhaqdhaqaaqa toosan ee tiirka (dhidibka X) awoodda matoorka servo | 3.1kw | |

| Xawaaraha ugu badan ee dhaqaaqa ee dhidibka X | 10m/daqiiqo | |

| Xawaaraha ugu badan ee dhaqdhaqaaqa ee Y, Z dhidibka | 8m/daqiiqo | |

| Nuugista magnet-ka joogtada ah ee korontada ku shaqeeya | Tirada | 1 qaybood |

| Cabbirka nuugista (L × w × h) | 250 × 200 × 120mm | |

| Nuugista shaqaynta | ≥200N/cm² | |

| Dhululubo riix dhinaca ah | Dhexroorka dhululubada × istaroog | Φ50 × 70mm |

| Riix dhinaca dhululubo ah oo keliya | 700Kg | |

| Miiska duubista ee kor u qaadaya | Tirada | 1 qaybood |

| Xawaaraha gudbinta | ≤15m/daqiiqo | |

| Silsilad gacan-qabsi ah oo hoos u haysa | Tirada | 1 qaybood |

| Xoogga cadaadiska | ≥1500Kg/set | |

| Ka saarista jajabka | Nooca gudbiyaha jajabka | Silsilad fidsan |

| Xawaaraha ka saarista jajabka | 2m/daqiiqo | |

| Awoodda matoorka ka saarista chip | 2.2kW | |

| Nidaamka Haydarooliga | Tirada | 2 qaybood |

| Cadaadiska / socodka / awoodda bamka haydarooliga | 6-6.5Mpa/25L/daqiiqo/4kW 1 set | |

| Cadaadiska / socodka / awoodda bamka haydarooliga | 5.5-6Mpa/66L/daqiiqo/7.5kW 1 set | |

| Nidaamka korontada | Nidaamka xakamaynta tirooyinka | Siemens 828D |

| Tirada faasaska CNC | 5+1 | |

| Isha hawada | Cadaadiska saadka hawada ee la cadaadiyay | 0.6Mpa |

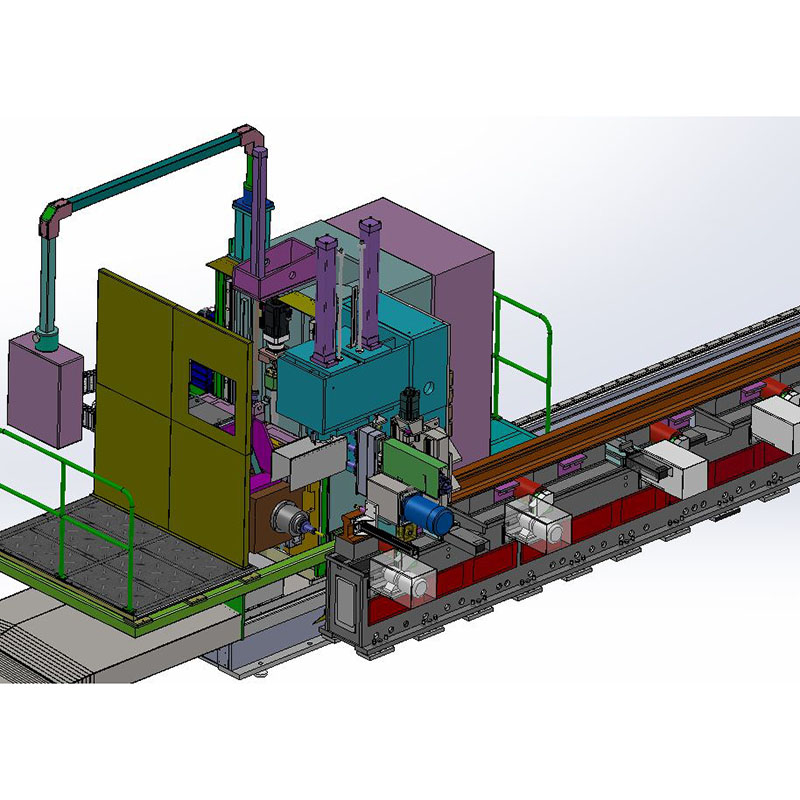

| Cabbirrada guud | (D× D× H) | Qiyaastii 57×8.7×3.8m |

1. Sariirta mashiinka waxaa laga soocay miiska shaqada, labada lammaane ee lammaane ee lammaane ee lammaane ee lammaane ee lammaane ayaa si toosan loo habeeyay si loo kordhiyo cimriga adeegga ee lammaane ee lammaane ee lammaane; Qaab-dhismeedka saxanka birta ah ee la alxanka leh ayaa la qaatay, saxnaanta iyo xasilloonidana waxaa lagu hubiyaa daadinta, yareynta walbahaarka iyo daaweynta gabowga macmalka ah.

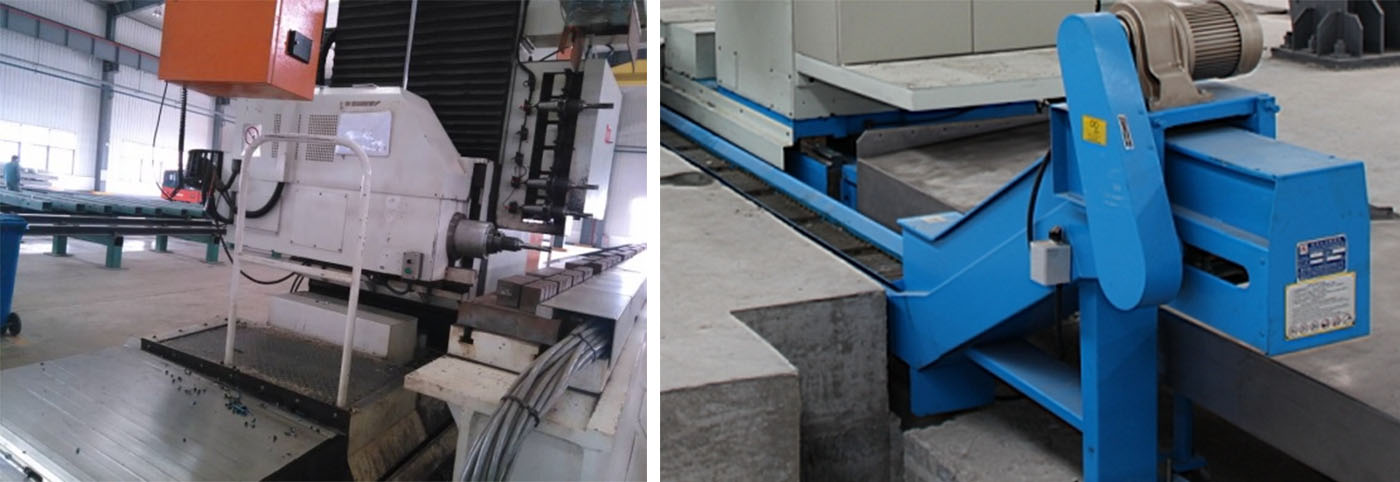

2. Waxaa lagu rakibay qalab koronto oo awood badan oo ku shaqeeya miiska shaqada ee qalabka mashiinka si loo adkeeyo agabka. Fiiro gaar ah u yeelo dalabka laga bilaabo bartamaha ilaa labada dhinac marka qalabka korontada ee la xiro, oo fiiro gaar ah u yeelo shaabadda iyo biyaha aan biyuhu gelin.

3. Tiirka guurguura wuxuu qaataa qaab-dhismeedka alxanka birta ah, kaas oo la dahaadhay si looga saaro walbahaarka iyo daaweynta gabowga macmalka ah si loo hubiyo xasilloonida saxda ah.

4. Qalabka siligga ee otomaatiga ah ee ka saara jajabka waa nooc silsilad fidsan, waxaana lagu rakibay bartamaha miiska shaqada ee sariirta.

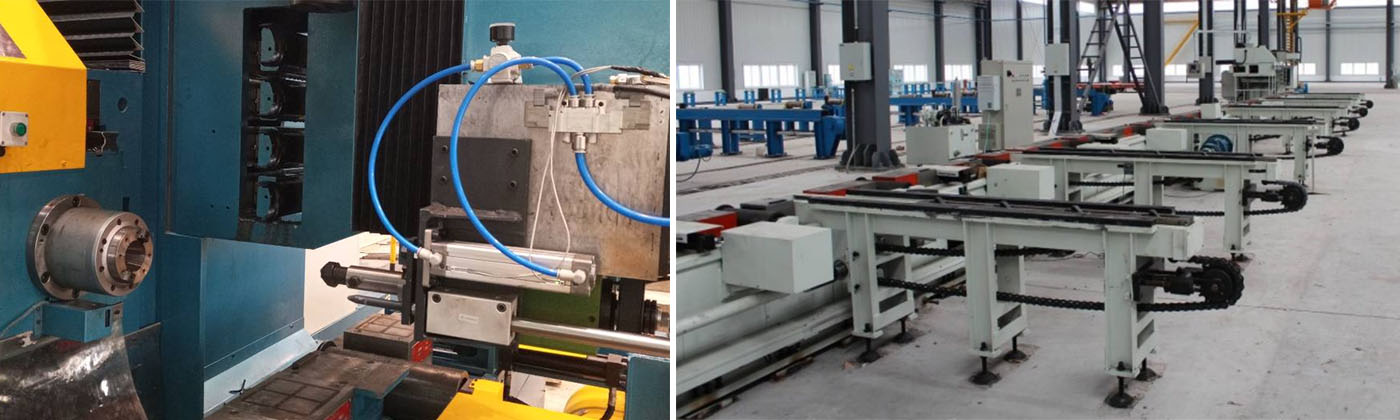

5. Mashiinku wuxuu ku qalabaysan yahay laba saldhig oo haydarooli ah, midna waxaa lagu rakibay tiirka guurguura, kaas oo inta badan loo isticmaalo isku dheellitirka dhululubada, dhululubada riixista iyo dhululubada mindiyaha; mid kalena waxaa lagu rakibay aasaaska, kaas oo inta badan loo isticmaalo qaadista dhululubada iyo jiidista dhululubada miiska qaadida.

6. Waxaa ku jira saddex faas oo CNC ah mashiinka, mid walbana waxaa hagaya lammaane hagaha toosan ee toosan.

7. Qalabka qodista wuxuu qaataa dalooliyaha carbide-ka ee indexable, waxaana qaboojiya wareegga hawada.

8. Nidaamka Siemens 828D CNC waxaa loo isticmaalaa nidaamka CNC, kaas oo la socon kara habka qodista waqtiga dhabta ah.

| NO. | Magaca | Summada | Waddan |

| 1 | Labada hagaha kubadda | HIWIN/PMI | Taiwan (Shiinaha) |

| 2 | CNCnidaamka | Siemens 828D | Jarmalka |

| 3 | Smatoorka ervo | Siemens | Jarmalka |

| 4 | Waalka Haydarooliga | ATOS | Talyaaniga |

| 5 | Bamka saliidda | Justmark | Taiwan (Shiinaha) |

| 6 | Silsilad jiidid | IGUS/CPS | Jarmalka / Kuuriya |

| 7 | Matoorka adeegga dunmiiqa | Siemens | Jarmalka |

| 8 | Qalab yareeya | ATLANTA | Jarmalka |

| 9 | dunmiiqa saxda ah | Kenturn | Taiwan (Shiinaha) |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga