RDS13 CNC Tareenka Miinshaar iyo Qoditaan Isku Jir ah Khadka Wax Soo Saarka

| Shay | xuduudaheedu | Faahfaahinta |

| Qaabka tareenka aasaasiga ah | Nooca qalabka | 50Kg/m,60 Kg/m,75 Kg/m adkaansho 340~400HB |

| Birta birta ah ee birta ah, birta birta ah ee birta ah, adkaanta 38 HRC~45 HRC | ||

| Cabbirka tareenka | Dhererka walxaha ceeriin | 2000~1250mm |

| Shuruudaha ka baaraandegidda | Alaabdhererka | 1300~800mm |

| Alaabdulqaadka dhererka | ±1mm | |

| Wajiga dhammaadka oo toosan | <0.5mm | |

| Dhexroorka qodista | φ31~φ60mm | |

| Dhexroorka godkadulqaad | 0~0.5mm | |

| Heerka dhererka godka | 60~100mm | |

| Xuduudaha farsamada ee ugu muhiimsan ee mashiinka | Habka jarista | Miinshaar wareeg ah (xawaare sare) |

| Awoodda matoorka dunmiiqa | 37kW | |

| Dhexroorka daab miinshaar | Φ660mm | |

| Xawaaraha ugu badan ee dhaqaaqa ee dhidibka X | 25m/daqiiqo | |

| Xawaaraha ugu badan ee dhaqaaqa ee dhidibka Z | 6m/daqiiqo | |

| Nooca dunmiiqa qodista | BT50 | |

| QodistaXawaaraha dunmiiqa | 3000r/daqiiqo | |

| QodistaAwoodda matoorka adeegga dunmiiqa | 37kW | |

| Xawaaraha ugu badan ee dhaqaaqa ee dhidibka X, Y, iyo Z | 12m/daqiiqo | |

| Nooca dunmiiqa Chamfering | NT40 | |

| Spindle-ka Chamfering RPM ugu badnaan. | 1000 | |

| Awoodda matoorka wareegga ee Chamfering | 2.2 kW | |

| Xawaaraha dhaqdhaqaaqa ee dhidibka Y2 iyo dhidibka Z2 | 10m/daqiiqad | |

| Jeelka magnetic-ka ee joogtada ah ee korontada ku shaqeeya | 250 × 200 × 140mm (mid kale200 × 200 × 140mm) | |

| Nuugista shaqada | ≥250N/cm² | |

| Nidaamka ka saarista jajabka | 2dejisan | |

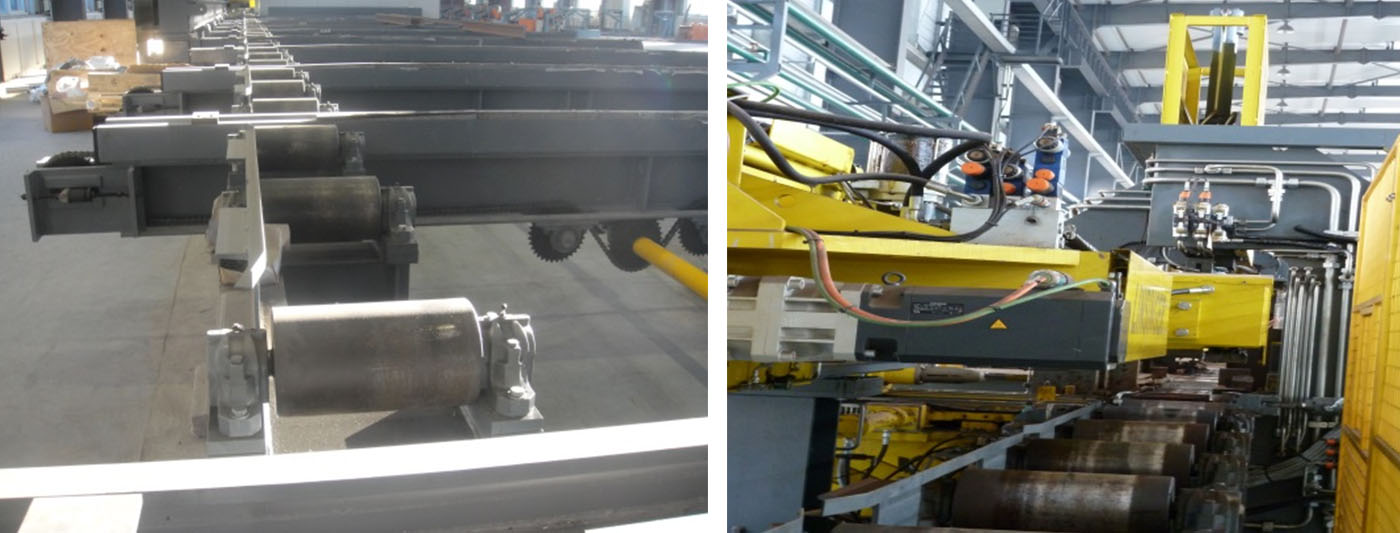

| Nooca gudbiyaha jajabka | Silsilad fidsan | |

| Xawaaraha ka saarista jajabka | 2m/daqiiqo | |

| Nidaamka CNC | Siemens828D | |

| Tirada nidaamyada CNC | 2 qaybood | |

| Tirada faasaska CNC | 6+1dhidib,2+1 dhidib | |

| Dhererka miiska shaqada | 700mm | |

| Dhererka miiska shaqada | qiyaastii 37.8m×8m×3.4m |

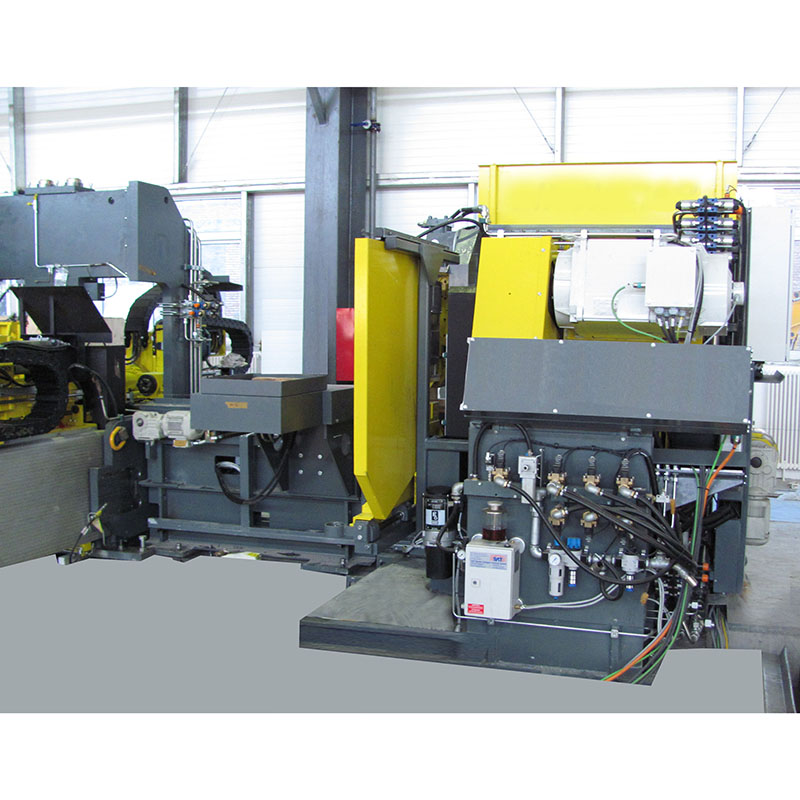

1. Waxaa ku yaal qalab ka saarista jajabka daab miinshaar ah oo ku yaal qaybta jarista, kaas oo mas'uul ka ah ka saarista balka miinshaar. Qalabka qaboojinta iyo saliidaynta ayaa saliideeya oo qaboojiya aagga jarista, taas oo hagaajinaysa cimriga adeegga daabka miinshaar. Biraha hagaha, tiirka guurguura ayaa lagu rakibay sariirta mashiinka.

2. Nidaamka codeynta

Nidaamka codeynta waxaa lagu rakibay dhinaca dibadda ee ram-ka madaxa korontada, waxaana ku qalabaysan kombuyuutar martigelinaya si uu u barnaamijiyo una xakameeyo nidaamka codeynta.

3. Qalabka qodista

Qaab-dhismeedka tiirka ayaa la qaataa, tiirkuna wuxuu qaataa qaab bir ah oo lagu dahaadhay saxan bir ah. Ka dib marka la nadiifiyo oo la daweeyo gabowga macmalka ah, waxaa la hubiyaa xasilloonida saxnaanta habaynta.

4. Qodista madaxa

Madaxa qodista waa qaab-dhismeed nooca ram ah oo leh adkeysi xooggan. Suunka waqtiga wuxuu leeyahay xoog jiidis sare, cimri dheer, buuq yar iyo gariir hooseeya marka uu ku shaqeynayo xawaare sare. Isgoyska saxda ah gudaha waa la qaboojiyey oo godan yahay, waxaana lagu qalabeeyay farsamo cidhib afar geesle ah oo 45° ah. Dhammaadka dambe ee isgoyska saxda ah waxaa lagu qalabeeyay dhululubo feer haydarooliga ah si loogu beddelo qalabka si fudud.

5. Miiska Shaqada

Shaqada miiska waxay qaadataa qaab-dhismeedka alxanka birta ah, daaweyn hore ayaa la sameeyaa ka hor alxanka, ka dib alxanka, yareynta cadaadiska iyo daaweynta gabowga kulaylka ayaa la sameeyaa si loo hubiyo saxnaanta iyo xasilloonida.

6. Nidaamka ka saarista Chip

Qalabka gudbiyaha jajabka ee otomaatiga ah waa nooc silsilad fidsan, oo wadartiisu tahay laba qaybood. Hal qaybood ayaa loo isticmaalaa qaybta jarista iyo waxaa la dhigaa dhinaca miinshaarta. Qaybta kale waxaa loo isticmaalaa qaybta qodista, kaas oo la dhigo inta u dhaxaysa sariirta iyo kursiga shaqada. Faylasha birtu waxay ku dhacaan qalabka gudbiyaha jajabka iyada oo loo marayo hagaha jajabka ee ku yaal kursiga shaqada, faylasha birtana waxaa loo qaadaa sanduuqa faylalka birta ee madaxa iyada oo loo marayo qalabka gudbiyaha jajabka.

7. Nidaamka saliidaynta

Waxaa jira laba qaybood oo ah nidaamyada saliidaynta otomaatiga ah ee dhexe, mid loogu talagalay cutubka jarista iyo kan kale ee cutubka qodista. Nidaamka saliidaynta otomaatiga ah wuxuu sameeyaa saliidayn kala go'an oo ku saabsan lammaanaha hagaha toosan ee rogista, lammaanaha boolal kubbadda, iyo lammaanaha raafka iyo pinion si loo hubiyo saxnaantooda iyo cimrigooda adeegga.

8. Nidaamka korontada

Nidaamka korontada wuxuu qaataa nidaamka xakamaynta tirooyinka ee Siemens 828D, wadarta laba qaybood, hal qayb ayaa loo isticmaalaa in lagu xakameeyo qaybta jarista, qaybta quudinta ee toosan, miiska duubista quudinta iyo miiska duubista ee dhexe. Qaybta kale waxaa loo isticmaalaa in lagu xakameeyo qaybta qodista, kursiga shaqada 1, qaybta dejinta ee toosan iyo kursiga shaqada.

| MAYA. | Shay | Summada | Asal ahaan |

| 1 | Labada hagaha toosan | HIWIN | Taiwan, Shiinaha |

| 2 | Nidaamka CNC 828D | Siemens | Jarmalka |

| 3 | Smatoorka ervo | Siemens | Jarmalka |

| 4 | Nidaamka codeynta | Daabacaha LDInkjet | Shanghai, Shiinaha |

| 5 | bamka saliidda Haydarooliga | Justmark | Taiwan, Shiinaha |

| 6 | Silsilad jiidid | CPS-ka | Kuuriyada Koonfureed |

| 7 | Geesaska, raafka | APEX | Taiwan, Shiinaha |

| 8 | Hoos u dhigista saxda ah | APEX | Taiwan, Shiinaha |

| 9 | dunmiiqa saxda ah | KENTUR | Taiwan, Shiinaha |

| 10 | Qaybaha ugu muhiimsan ee korantada | Schneider | Faransiiska |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga