Mashiinka Jarjarka Tareenka CNC ee RS25 25m

| Qeexitaanka tareenka la warshadeeyay | Tareenka kaydka | 43Kg/m,50Kg/m,60Kg/m,75Kg/m iwm. |

| Birta qaybta aan sinnayn | 60AT1,50AT1,60TY1,UIC33 iwm.. | |

| Dhererka ugu badan ee tareenka ka hor inta aan la jarin | 25000mm (It sidoo kale waxaa loo isticmaali karaa biraha 10m ama 20m, iyadoo shaqada lagu cabbirayo dhererka alaabta ceeriin.) | |

| Dhererka miinshaarta ee tareenka | 1800mm~25000mm | |

| Qalabka jarista | Habka jarista | Goynta Oblique |

| Xagasha goynta ee oblique | 18° | |

| kale | nidaamka korontada | Siemens 828d |

| Habka qaboojinta | Qaboojinta ceeryaamo saliid | |

| nidaamka xoqidda | Isku-xidhka toosan iyo kan jiifa, oo lagu hagaajin karo haydarooliga | |

| Qalabka quudinta | Tirada meelaha lagu quudiyo | 7 |

| Tirada biraha la dhigi karo | 20 | |

| Xawaaraha ugu badan ee dhaqaaqa | 8m/daqiiqo | |

| Miiska duubista quudinta | Xawaaraha ugu badan ee gaarsiinta | 25m / daqiiqo |

| Aaladda wax lagu faaruqiyo | Tirada raafka bannaan | 9 |

| Tirada biraha la dhigi karo | 20 | |

| Xawaaraha ugu badan ee dhaqdhaqaaqa dhinaca | 8 m / daqiiqo | |

| Cutubka sawirka | Xawaaraha sawir-qaadista ugu badan | 30 m / daqiiqo |

| Nidaamka Haydarooliga | 6Mpa | |

| Enidaamka korontada | Siemens 828D |

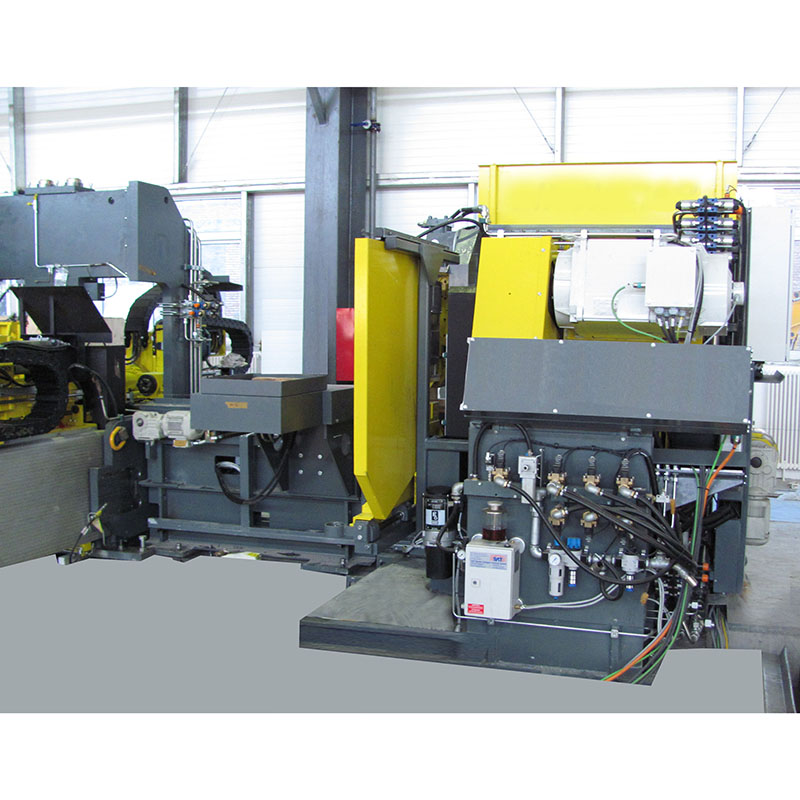

1. Qalabka quudinta wuxuu ka kooban yahay 7 kooxood oo ah qaababka quudinta. Waxaa loo isticmaalaa in lagu taageero tareenka oo lagu jiido tareenka si loogu riixo tareenka lagu farsameeyo meesha lagu quudiyo miiska duubista.

2. Miiska rogrogmada ee dejintu wuxuu ka kooban yahay dhowr kooxood, mid walbana si madax-bannaan ayaa loo wadaa oo loo qaybiyaa inta u dhaxaysa qaab-dhismeedka rarista si loo taageero tareenka loona qaado tareenka ilaa cutubka jarista.

3. Matoorka wareegga waxaa ku xiran qalabka yareeya suunka isku-xidhka ah, ka dibna wuxuu wadaa wareegga jarista. Dhaqdhaqaaqa daabka miinshaarta waxaa hagaya laba lammaane oo hagayaal toosan oo leh awood sare oo qaadis ah oo ku dheggan sariirta. Matoorka servo waxaa ku shaqeeya suunka isku-xidhka ah iyo lammaane boolal ah oo kubbadda ah, kuwaas oo fulin kara hore u socoshada degdegga ah, hore u shaqaynta, dib u noqoshada degdegga ah iyo falalka kale ee daabka miinshaarta.

4. Inkjet waa dhakhso badan yahay, jilayaashu waa cad yihiin, waa qurux badan yihiin, ma dhacayaan, ma libdhinayaan. Tirada ugu badan ee jilayaashu waa 40 markiiba.

5. Qalab jajaban oo silsilad fidsan ayaa lagu rakibayaa sariirta qaybta jarista, kaas oo ah qaab-dhismeed madax-ilaa-sare ah isla markaana jajabyada birta ah ee laga soo saaro jarista ku sii daaya sanduuqa jajabka birta ee dibadda.

6. Waxaa lagu qalabeeyay qalab qaboojiye oo saliid ceeryaamo ah si loogu qaboojiyo miinshaarta si loo hubiyo cimrigeeda. Tirada ceeryaamo saliideed waa la hagaajin karaa.

7. Mashiinku wuxuu ku qalabaysan yahay qalab saliidayn oo otomaatig ah oo dhexe, kaas oo si toos ah u saliidayn kara lammaanayaasha hagaha toosan, lammaanayaasha boolal kubbadda, iwm. Hubi xasilloonida mashiinka.

| MAYA. | Magaca | Summada | Faallo |

| 1 | Labada hagaha toosan | HIWIN/PMI | Taiwan, Shiinaha |

| 2 | Nidaamka xakamaynta tirooyinka | Siemens | Jarmalka |

| 3 | Matoorka Servo iyo darawalka | Siemens | Jarmalka |

| 4 | Kombiyuutarka sare | Lenovo | Shiinaha |

| 5 | Nidaamka daabacaadda inkjet | LDM | Shiinaha |

| 6 | Qalabka iyo raafka | APEX | Taiwan, Shiinaha |

| 7 | Hoos u dhigista saxda ah | APEX | Taiwan, Shiinaha |

| 8 | Qalabka isku-hagaajinta laysarka | JIRAN | Jarmalka |

| 9 | Miisaanka birlabta | SIKO | Jarmalka |

| 10 | Waalka Haydarooliga | ATOS | Talyaaniga |

| 11 | Nidaamka saliidaynta otomaatiga ah | HERG | Jabaan |

| 12 | Qaybaha ugu muhiimsan ee korantada | Schneider | Faransiiska |

Fiiro gaar ah: Kan kor ku xusan waa alaab-qeybiyahayaga caadiga ah. Waxaa lagu beddeli karaa qaybo tayo leh oo la mid ah kuwa kale haddii alaab-qeybiyaha kor ku xusan uusan keeni karin qaybaha haddii ay dhacdo arrin gaar ah.

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga