Mashiinka Qodista CNC ee S8F ee laba-jibbaaran

| Magaca halbeegga | Cutubka | Qiimaha halbeegga | ||

| xuduudaha habka jir | Alaab | Bir kulul oo la duubay 16MnL | ||

| Xoogga ugu badan ee la jiidi karo | MPA | 1000 | ||

| Xoogga Wax Soo Saarka | MPA | 700 | ||

| Dhumucda ugu badan ee qodista | mm | 40(Loox lakab badan leh) | ||

| Habaynta istaroogga | dhidibka | mm | 1600 | |

| Dhidibka Y | mm | 1200 | ||

| Ku dhejinta dhinaca mobilada | dhidibka | mm | 500 | |

| Xaxis | mm | 500 | ||

| dunmiiqa qodista | tiro | gabal | 2 | |

| Isgoyska | BT40 | |||

| kala duwan oo dhexroor qodista | mm | φ8~φ30 | ||

| Masaafada ugu yar ee qodista madaxyada laba-geesoodka ah isla waqtigaas | mm | 295 | ||

| Ku quudi garaac | mm | 450 | ||

| Xawaaraha wareega | r/daqiiqad | 50-2000(Servo stepless) | ||

| Heerka quudinta | mm / daqiiqo | 0~8300 (Servo stepless) | ||

| Awoodda matoorka adeegga dunmiiqa | kW | 2 × 7.5 | ||

| Xuddunta lagu qiimeeyay dunmiiqa | Nm | 150 | ||

| Wareegga iswada | Nm | 200 | ||

| Xoogga quudinta dunmiiqa ugu badan | N | 7500 | ||

| Joornaalka Qalabka | TIRADA | gabal | 2 | |

| Foomka gacanka | BT40 (Iyada oo leh daloolin qalloocan oo shank ah oo caadi ah) | |||

| Awoodda majaladda qalabka | gabal | 2 × 4 | ||

| Nidaamka CNC | Chabka xakamaynta | Nidaamka Siemens 840D SL CNC | ||

| Tirada faasaska CNC | gabal | 7+2 | ||

| Awoodda matoorka adeegga | Xaxis | kW | 4.3 | |

| Dhidibka Y | 2x3.1 | |||

| dhidibka Z | 2x1.5 | |||

| Xaxis | 1.1 | |||

| Xaxis | 1.1 | |||

| Nidaamka Haydarooliga | Cadaadiska shaqada ee nidaamka | MPA | 2~7 | |

| nidaamka qaboojinta | Chabka loo isticmaalo | Habka qaboojinta hawada ee Aerosol | ||

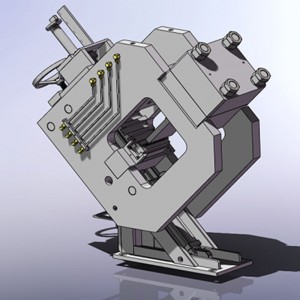

1. Mashiinka ugu weyn waxaa inta badan ka mid ah sariir, qalab dhaqaaqa, madaxa korontada qodista (2) (qodista qodista birta xawaaraha sare leh), farsamada beddelka qalabka (2), meelaynta, qalabka lagu xiro iyo ogaanshaha, iyo gaariga quudinta (2 A), nidaamka qaboojinta ee horumarsan, nidaamka haydarooliga, nidaamka CNC, daboolka ilaalinta iyo qaybaha kale.

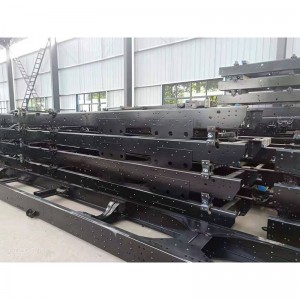

2. Mashiinku wuxuu qaataa qaabka sariirta go'an iyo qalabka la dhaqaajin karo.

3. Dhidibka Y ee toosan iyo dhidibka Z ee labada madax ee korontada qodista ayaa si madax-bannaan u dhaqaaqa. Dhaqdhaqaaqa dhidibka Y ee madax kasta oo koronto waxaa wada lammaane boolal oo gaar ah, kaas oo ka gudbi kara xariiqda dhexe ee walaxda; dhidib kasta oo CNC ah waxaa hagaya hage duubis toosan. Matoorka AC servo + darawalka boolal kubbadda. Madaxa korontada wuxuu leeyahay naqshad ka hortagta isku dhaca si looga hortago in madaxa korontada uu isku dhaco inta lagu jiro hawlgalka otomaatiga ah.

4. Madaxa korontada qodista wuxuu qaataa isteerinka saxda ah ee la soo dhoofiyay ee loogu talagalay xarunta mashiinka; wuxuu ku qalabaysan yahay god BT40 ah oo taper ah, waa ku habboon tahay in la beddelo qalabka waxaana lagu xiri karaa dhoobo kala duwan; isteerinka waxaa wada matoorka isteerinka servo, kaas oo buuxin kara shuruudaha xawaaraha kala duwan iyo shaqooyinka beddelka qalabka.

5. Si loo daboolo habaynta daloolada kala duwan, mashiinku wuxuu ku qalabaysan yahay joornaalada qalabka ee khadka tooska ah (2), laba madax oo awood ahna waxay xaqiijin karaan isbeddelka qalabka ee otomaatiga ah.

6. Mashiinku wuxuu leeyahay qalab madax-bannaan oo lagu ogaan karo otomaatig, kaas oo si toos ah u ogaan kara ballaca walxaha oo dib ugu celin kara nidaamka CNC.

7. Dhinac kasta oo sariirta mashiinka ah waxaa ku qalabaysan qalab laysar ah si loogu meeleeyo qaab dhismeedka qallafsan.

9. Mashiinku wuxuu ku qalabaysan yahay nidaam haydarooli ah, kaas oo inta badan loo isticmaalo meelaynta agabka iyo isku xidhka.

10. Mashiinku wuxuu ku qalabaysan yahay nidaam qaboojin ah oo loogu talagalay qodista iyo qaboojinta walxaha.

11. Qalabka mashiinka lagu xidho waxa uu leeyahay dabool ilaalin ah oo nooca xubnaha ah, halka qalabka sariirta lagu xidho uu leeyahay dabool ilaalin ah oo nooca saxanka ah oo telescopic ah.

12. Mashiinku wuxuu qaataa nidaamka xakamaynta tirooyinka ee Siemens 840D SL, kaas oo fulin kara barnaamijinta otomaatiga ah ee CAD wuxuuna leeyahay shaqada aqoonsiga lakabka. Nidaamku si toos ah ayuu u go'aamin karaa masaafada shaqada iyadoo loo eegayo dhererka qalabka (gelinta gacanta) iyo dhererka qaab-dhismeedka, guud ahaan 5mm, qiimahiisana waxaa loo dejin karaa iyadoo loo eegayo shuruudaha.

13. Mashiinku wuxuu ku qalabaysan yahay nidaam sawir-qaadis ah oo toosan (koodka bar-ka-hal-cabbir, heerka cod-bixinta ee CODE-128), kaas oo si toos ah ugu yeera barnaamijka farsamaynta isagoo sawiraya koodka bar-ka-toosan ee qaab-dhismeedka isagoo isticmaalaya iskaanka wireless-ka gacanta lagu qaato.

14. Mashiinku wuxuu leeyahay shaqada tirinta oo ah inuu si toos ah u ururiyo tirada godadka qodista iyo tirada walxaha la farsameeyay, mana la nadiifin karo; Intaa waxaa dheer, wuxuu leeyahay shaqo tirinta wax soo saarka, taas oo duubi karta tirada walxaha uu farsameeyo barnaamij kasta oo farsamayn ah, waana la weydiin karaa oo la nadiifin karaa.

| MAYA. | Shay | summad | Asal ahaan |

| 1 | Tilmaamaha Toosan | HIWIN/PMI | Taiwan, Shiinaha |

| 2 | dunmiiqa saxda ah | Kenturn | Taiwan, Shiinaha |

| 3 | Nidaamka iskaanka barcode-ka toosan | ASTAAMAHA | Ameerika |

| 4 | Nidaamka CNC | Siemens 840D SL | Jarmalka |

| 5 | Smatoorka ervo | Siemens | Jarmalka |

| 6 | Matoorka adeegga dunmiiqa | Siemens | Jarmalka |

| 7 | Qaybaha ugu muhiimsan ee Haydarooliga | ATOS | Talyaaniga |

| 8 | Silsilad jiidid | Misumi | Jarmalka |

| 9 | Qaybaha korontada ee danab hooseeya | Schneider | Faransiiska |

| 10 | Awood | Siemens | Jarmalka |

Warbixinta Kooban ee Shirkadda  Macluumaadka Warshadda

Macluumaadka Warshadda  Awoodda Wax-soo-saarka Sannadlaha ah

Awoodda Wax-soo-saarka Sannadlaha ah  Awoodda Ganacsiga

Awoodda Ganacsiga